If you're in manufacturing, you're likely under pressure to reduce costs, boost efficiency, and tackle labour shortages - all while keeping quality high. That’s where bespoke collaborative robots, or cobots, come in. Unlike traditional industrial robots, cobots work safely in close proximity to human workers, slotting neatly into your existing processes.

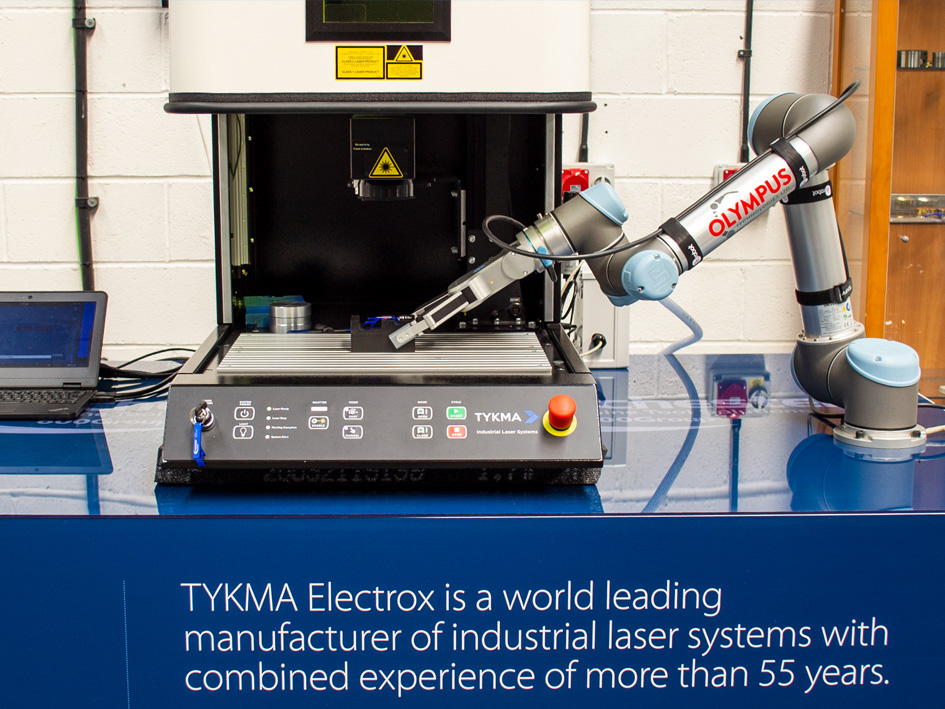

At Olympus Technologies, we specialise in helping businesses like yours take advantage of collaborative robotics, offering fully integrated, user-friendly robot solutions from our base in Huddersfield.

What Are Collaborative Robots?

Collaborative robots are designed to work safely alongside humans, equipped with advanced sensors and artificial intelligence to handle a wide range of tasks with precision. They’re flexible, easy to program, and perfectly suited for modern manufacturing environments where agility is key. Whether you're looking to automate repetitive tasks or introduce more consistency to your processes, cobots offer a scalable, future-ready solution source.

Human-Robot Collaboration (HRC): Teamwork That Works

Human-robot collaboration (HRC) is all about bringing the best of both worlds together - robot precision and human problem-solving. It’s not about replacing people, but freeing them up from physically demanding tasks to focus on roles where their skills add more value.

Benefits include:

- Safer workplaces thanks to force and proximity sensors.

- More flexibility for mixed production lines.

- A boost in overall process efficiency.

We design collaborative systems that make the transition seamless, ensuring your team is confident and comfortable working with their new robot co-workers.

Why Go Bespoke?

Every business is different, and that’s why we don’t believe in one-size-fits-all solutions. A bespoke cobot setup is tailored to your specific production needs - meaning better outcomes, less waste, and faster results.

Key Benefits:

- Reduce your manufacturing costs by automating repetitive, high-precision tasks.

- Improve product quality and reduce rework.

- Run operations around the clock with lights out operations.

- Protect your team from strain and injury.

Whether you're in metal fabrication, palletising, or vision inspection, we’ll work closely with you to deliver a setup that hits the mark.

Cobots vs. Traditional Industrial Robots

| Feature | Traditional Robots | Collaborative Robots (Cobots) |

|---|---|---|

| Work Environment | Fenced, isolated | Shared, minimal guarding |

| Setup Time | Weeks or months | Days or weeks |

| Programming | Complex, expert-only | Easy, intuitive (even no-code) |

| Flexibility | Limited to single tasks | Reprogrammable for different tasks |

| Ideal Use Case | High-volume, single-task | Small-batch, dynamic production |

Cobots offer the flexibility and ease of use modern manufacturers need to stay competitive.

Where Cobots Make the Biggest Impact

In the Automotive Industry

Cobots are already transforming automotive production, taking care of:

- Assembly tasks like fastening and screwdriving.

- Welding, sealing, and even vision-based quality checks.

- Material handling and transfer between stations.

With reduced cycle times and consistent results, the gains speak for themselves.

For Material Handling

Struggling with heavy lifting or endless pick-and-place? Cobots shine in:

- Palletising and case packing.

- Sorting and machine tending.

- Reducing damage to parts and speeding up your supply chain.

These solutions are particularly popular in end-of-line automation, one of our specialist areas at Olympus Technologies.

How Cobots Help You Cut Production Costs

This is where the numbers start looking really good. By automating manual or repetitive tasks, cobots help:

- Lower labour costs, especially where skilled workers are hard to find.

- Cut energy consumption, as robots can be programmed for optimal efficiency.

- Reduce material waste through consistent quality.

- Minimise downtime, operating 24/7 with minimal supervision.

All of this adds up to a healthier bottom line and faster return on investment (ROI).

Cobots for a Wide Range of Industries

While we’ve built a strong reputation in metal manufacturing, machine tending, and palletising, cobots are making waves across sectors like:

- Medical devices

- Consumer electronics

- Food and beverage

- Pharmaceuticals

Their adaptability means you can use the same robot arm across multiple applications or production lines, responding quickly to new opportunities.

Thinking of Getting Started?

Here’s how we guide our clients through a smooth cobot journey:

- Identify the pain points in your current workflow.

- Choose the right cobot model based on the task, reach, and payload.

- Integrate seamlessly with your existing equipment (we’ve got the robot software plug-ins to make it easy).

- Train your team to operate and troubleshoot confidently.

- Monitor your KPIs and refine the setup as needed.

Common Challenges? We’ve Got You Covered

| Challenge | Olympus Solution |

|---|---|

| Integration worries | Modular, open API cobot setups |

| Team scepticism | Hands-on training and early involvement |

| Safety concerns | Thorough risk assessments and safety tools |

| Proving ROI | Transparent metrics on quality and savings |

Real Businesses, Real Results

- Bart Ingredients, a renowned UK-based spice and seasoning producer increased productivity by 33% using our palletising cobot - Read Bart Ingredients Case Study here.

- ADS Laser Cutting, the premier metal laser cutting, folding, fabrication, finishing & assembly provider in the UK cut project turnaround times by 50% with our MIG welding cobot - Read ADS Laser Cutting Case Study here.

- Schiedel Chimney Systems, the leading flue and chimney manufacturer in the UK and ROI saw an 11% increase in productivity with our machine tending solution - Read Schiedel Chimney Systems Case Study here.

These aren’t one-off wins - they’re examples of what’s possible when you integrate cobots with intent.

Best Practices for Long-Term Success

- Choose the right tool for the specific task.

- Prioritise systems that are safe, scalable, and simple to use.

- Always test before scaling.

- Track the right KPIs.

- Keep training and support ongoing - we’ll be here every step of the way.

Final Thoughts

When you invest in bespoke collaborative robots, you're not just automating a process - you’re future-proofing your business. From reducing production costs to improving safety and maintaining consistent quality, the benefits speak for themselves.

At Olympus Technologies, we don’t just sell robots - we build smart, adaptable solutions that work closely with your team to deliver real value. If you're ready to explore how cobots can transform your operations, we're here to help you make it happen. Get in contact with the team here.

Frequently Asked Questions (FAQs)

How can cobots improve manufacturing processes?

Cobots streamline manufacturing processes by automating repetitive or physically demanding tasks. This allows human workers to focus on more complex roles, increasing both output and overall process efficiency.

What does "improving process efficiency" really mean?

Improving process efficiency means doing more in less time with fewer resources. Cobots help by performing tasks with consistent speed and accuracy, reducing delays, errors, and waste.

Is the manufacturing sector ready for collaborative robotics?

Absolutely. The manufacturing sector is increasingly embracing collaborative robotics to stay competitive, especially as product cycles shorten and customisation becomes more important.

What types of tasks can robotic arms perform?

Modern robotic arms can handle a wide variety of jobs, from machine tending and welding to palletising and vision inspection. They’re adaptable enough to perform different tasks with minimal reconfiguration.