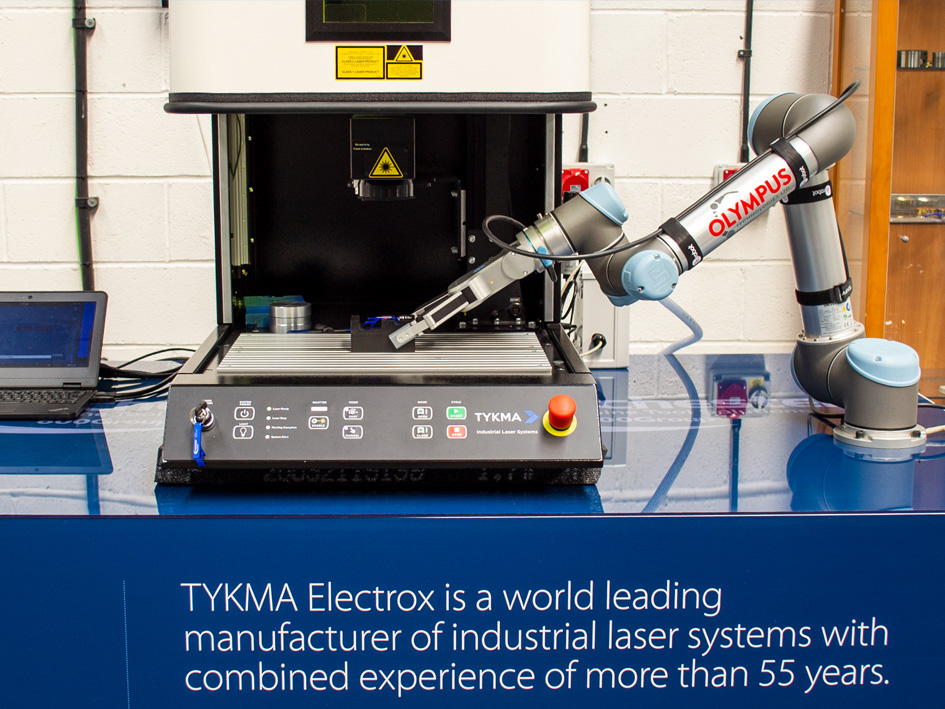

At Olympus Technologies, we’re all about helping manufacturers embrace automation with confidence. Based in Huddersfield, we’re a leading cobot and robot integrator designing smart, safe, and simple robot solutions for businesses across the UK and beyond.

Whether you’re dealing with repetitive tasks on the factory floor or want to improve your quality control without piling pressure on your team, our collaborative robots (cobots) are designed to work alongside human workers. Think of them as your reliable, tireless teammates.

Why Choose Cobots?

Unlike traditional industrial robots, cobots come with advanced built-in safety features, including collision detection and force-limiting technology, so they can safely perform complex tasks with very minimal guarding. That’s a huge win for efficiency and safety.

And it gets better: cobots offer cost-effective operations, enhanced productivity, and consistent product quality, all without needing major changes to your existing machinery.

We're proud to work with Universal Robots, a leader in the field, known for intuitive, plug-and-play models that are ideal for a wide range of industrial applications (Universal Robots, 2024).

Step 1: Lay the Groundwork for Automation

A successful cobot implementation starts with clear planning. At Olympus Technologies, we work closely with you to understand your production processes and identify opportunities for robotic integration.

Here's what we look at:

| Planning Task | Purpose |

|---|---|

| Identify repetitive or hazardous jobs | Perfect candidates for cobots |

| Review existing equipment and processes | Ensure seamless integration |

| Analyse cycle times and payloads | Choose the right robotic arm |

| Perform risk assessments | Align with ISO/TS 15066 safety standards & BS EN ISO 10218-2:2025 |

| Develop training programmes | Equip teams with practical knowledge and safety protocols |

From welding to palletising, our team makes sure your cobots are deployed where they’ll make the biggest impact - safely and effectively.

Step 2: Integrate Cobots into Your Production Line

We don’t just sell you a robot - we design and integrate bespoke robotic systems that fit into your operations like a glove. Whether it's a machine tending setup in a metal workshop or a packaging system for your end-of-line processes, we make sure your cobot's tasks align with your business goals.

By using simulation software and real-time monitoring, we help you plan ahead, tweak workflows, and get optimal performance right from the start.

Step 3: Automate Precision Assembly Tasks

Cobots are built for accuracy. If your process involves assembling delicate parts, performing quality inspection, or managing complex instructions, we’ve got you covered.

Thanks to their advanced sensors, machine vision, and graphical interfaces, cobots help reduce errors while boosting consistency and product quality.

Step 4: Scale Up Your Automation

Looking to build a smart factory? Cobots are your stepping stone. We can help you integrate them into larger automation systems for total visibility and control.

Expect:

- Fewer stoppages

- Predictive maintenance

- Better production speed and scalability

With Olympus Technologies as your integration partner, you’ll always be ready for the next stage of digital transformation.

Step 5: Keep Control Simple

Our robot software plug-ins are designed to make operation straightforward - no need to be a programming expert.

From touchscreen HMIs to drag-and-drop graphical user interfaces, your team can get up to speed quickly. But if you're tackling complex tasks or want more control, we also also develop custom URCaps to simplify complex functionality.

We offer tiered training that covers everything from basic operation to advanced automation strategies.

Step 6: Stay Ahead with Ongoing Support

To maintain safety and performance, we recommend preventative maintenance and continuous monitoring. We can offer support with:

- Firmware and software updates

- Diagnostic checks and log file analysis

- On-site and telephone support

With predictive maintenance and routine servicing, your cobots stay in top form - delivering reliable, high-precision performance every shift.

Step 7: Track Performance and ROI

Wondering how to measure your cobot’s impact? We track key performance metrics to help you see real results:

| Metric | What It Means | Typical Improvement |

|---|---|---|

| Cycle Time | Speed per job | 20–50% faster |

| Defect Rate | Errors per unit | ≤1% |

| Labour Efficiency | Output per worker-hour | 30 - 60% more efficient |

| ROI Payback | Time to break even | 18 months on average |

These figures help you refine your strategy and support continuous improvement.

Step 8: Fill Labour Gaps with Confidence

With skilled labour in short supply, cobots can take on time-consuming or physically demanding roles - freeing your team to focus on tasks that need a human touch.

We’ve seen the biggest gains in:

- Food and beverage

- Metal manufacturing

- Logistics and warehousing

And because cobots maintain safety and reduce strain, job satisfaction and workplace wellbeing go up too.

Need Expert Advice?

As an experienced robot and cobot integrator, we don’t just deliver machines - we offer solutions. Whether you need help with metal manufacturing, end-of-line automation, or something more niche, we’re happy to explore it with you - Get in contact with the team here.

Conclusion

At Olympus Technologies, we’re passionate about helping businesses like yours automate smarter. Our cobot solutions are flexible, efficient, and safe - designed to work hand-in-hand with your team and processes.

From initial risk assessment through to training, optimisation, and long-term support, we’re with you every step of the way. Let’s turn your automation goals into a reality - with robots that do the hard work, so your team can do their best work.

Frequently Asked Questions

What is a step-by-step guide to tailored cobot integration?

A step-by-step guide to tailored cobot integration walks you through the entire process - from identifying tasks like repetitive tasks and material handling, to selecting the right robotic systems, to deploying and training your team. At Olympus Technologies, we provide a fully customised approach that includes risk assessment, programming, installation, and continuous improvement support.

How do cobots work alongside human workers?

Collaborative robots are designed to work alongside human workers without the need for imposing safety cages. Thanks to built-in safety features like collision detection and force-limiting controls, they allow direct physical interaction while maintaining a high level of safety standards (ISO/TS 15066 & BS EN ISO 10218-2:2025).

What makes cobots different from traditional industrial robots?

Unlike traditional robots, cobots are smaller, more flexible, and come with advanced safety features. While traditional industrial robots often require isolated environments, cobots can operate independently within shared workspaces - making them ideal for modern manufacturing and cost-effective operations.