Why Traceability Matters More Than Ever

Traceability has become central to how manufacturers run their production lines.

As operations grow more complex, keeping track of components, materials, and all the parts that move through a facility is essential. Whether it’s for quality assurance, regulatory compliance, or supply chain visibility, knowing exactly where something came from - and where it’s going - is critical.

One tool that makes this possible is laser marking. By adding permanent identifiers to parts, laser marking ensures traceable data stays with each object throughout the entire manufacturing process. From medical devices to aerospace systems, it plays a key role in meeting industry demands across many industries.

What Laser Marking Is and How It Works

Laser marking uses a focused beam of light to make permanent marks on a surface. These marks - often barcodes, QR codes, or serialized data - connect each part to a broader data structure. That connection allows the part to be tracked, scanned, or logged into a software platform.

Different laser marking machines suit different materials. A fibre laser is often used for metal, offering depth and durability at high speed. For softer or sensitive surfaces like plastics or ceramics, UV or CO₂ options work better.

What sets laser technology apart is its precision, flexibility, and ability to work within automated systems. Unlike ink or mechanical methods, it requires no contact and leaves no mess - an important detail for clean manufacturing environments.

Why Laser Marking Supports Complete Traceability

A mark isn’t useful unless it’s durable, accurate, and integrated into a digital data structure. That’s where laser excels. The identifiers it creates - whether a code, symbol, or text - are readable by scanners and vision systems, feeding real-time information into MES or ERP software.

Laser-based marks are:

- Permanent, even in harsh environments

- Clean and contactless, reducing wear on equipment

- Flexible, working across a variety of materials

- Precise, down to micron-level detail, even on small or complex parts

These traits make laser marking ideal for tracking parts throughout a product’s lifecycle. From the moment an object enters a production cell, every process it goes through can be logged and verified.

Laser vs Traditional Marking Methods

To understand the benefits, it helps to compare laser marking with older approaches:

| Feature | Laser Marking | Inkjet Marking | Dot Peen | Chemical Etching |

|---|---|---|---|---|

| Permanence | High | Low | Medium | High |

| Maintenance | Low | Medium | Medium | High |

| Speed | Fast | Medium | Slow | Slow |

| Environmental Impact | Low | Medium | Low | High |

| Consumables Required | No | Yes | No | Yes |

For automated manufacturing systems, laser marking offers a cost-effective and low-maintenance solution. It aligns with fully integrated workflows where speed and data accuracy are priorities.

Integrating Laser Marking into Automation

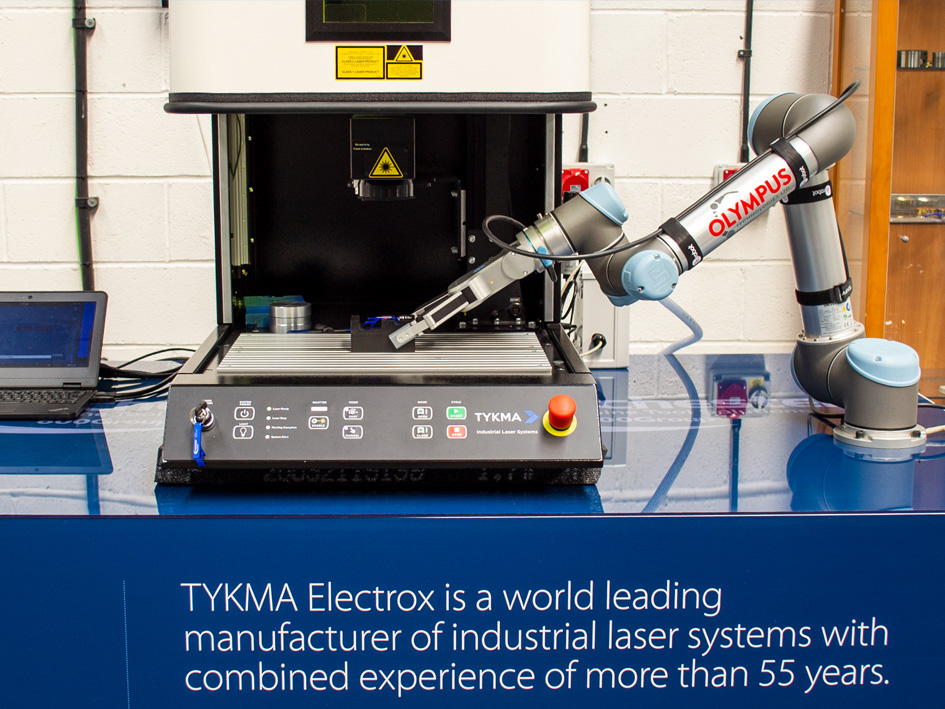

Instead of being a standalone step, laser marking machines can be built directly into automation lines. Whether mounted on conveyors, paired with robots, or integrated into inspection stations, they keep pace with modern production demands.

Once a mark is applied, its code is read and uploaded to a software platform - linking that component to a full history. That digital record can include:

- Where it came from in the supply chain

- Which raw materials were used

- Which programming language controlled the marking

- When it was inspected, packaged, or shipped

This is what enables true, complete traceability - every step logged, searchable, and connected.

Connecting Data Serialization with Laser Marking

Data serialization assigns each unit a unique identifier. That code can then be used across other systems, whether in the cloud or on-site. Laser marking provides the physical link to that digital identity.

Once applied, the mark connects the object to stored information, such as:

- Source, batch, or supplier details

- Time-stamped manufacturing processes

- Quality checks or error flags

- Shipping, ownership, or warranty records

This tight pairing between digital and physical assets gives native support for traceability across platforms. It also simplifies the deserialization process if the object needs to be identified outside its original system.

Industry Examples: Laser Marking in Action

Automotive

Used on engine blocks, safety systems, and more, laser-coded parts allow issues to be traced quickly. This supports quality assurance and speeds up recalls.

Medical Devices

Laser marks are used for UDI compliance, adding traceable data to surgical tools and implants. It helps ensure patient safety while meeting both FDA and EU standards.

Aerospace

Long-lifespan parts demand traceability through many years of service. Laser coding supports maintenance, audits, and defined performance checks.

Consumer Electronics and Goods

For new products, laser enables branding, anti-counterfeiting, and lifecycle tracking, protecting both the product and the brand.

A Traceability Interface for the Smart Factory

In a smart factory, where machines talk to one another and share data without human input, laser marking is the bridge between the physical and digital. It supports:

- Real-time inventory tracking

- Automated defect detection using AI

- Instant compliance reports

- Predictive maintenance based on mark visibility or wear

Its flexible capability to work across materials, formats, and data models makes it a powerful interface in any automation system.

Final Thoughts: A Defined Role in Future Manufacturing

For manufacturers looking to future-proof their operations, laser marking is no longer a secondary option. It delivers high-speed precision, integrates with modern software, and links physical components to digital records in a meaningful way.

Whether you're upgrading existing systems or launching a new plant, the ability to trace every object - accurately, efficiently, and permanently - starts with laser.

FAQs

What makes laser marking ideal for traceability?

Laser marking ensures each object has a permanent, scannable ID tied to a data structure, allowing seamless tracking across software platforms and systems.

Can laser marking be used with all materials?

Yes. Whether you’re working with metals, plastics, or composites, laser marking machines can adjust based on the material, offering both versatility and precision.

How does data serialization work with laser marking?

Data serialization assigns each item a unique code, which is then physically applied via laser and linked to stored information for full traceability.

Why is laser marking preferred over traditional methods?

It’s cleaner, faster, and more durable. With no consumables and low maintenance, it’s a better solution for fully integrated, automated manufacturing environments.