UR8 Long's extended reach combined with coordinated multi-axis motion allows for complex weldments at consistent quality. Motion performance optimisation also delivers smoother movements at maximum speed to significantly enhance fast-paced bin picking.

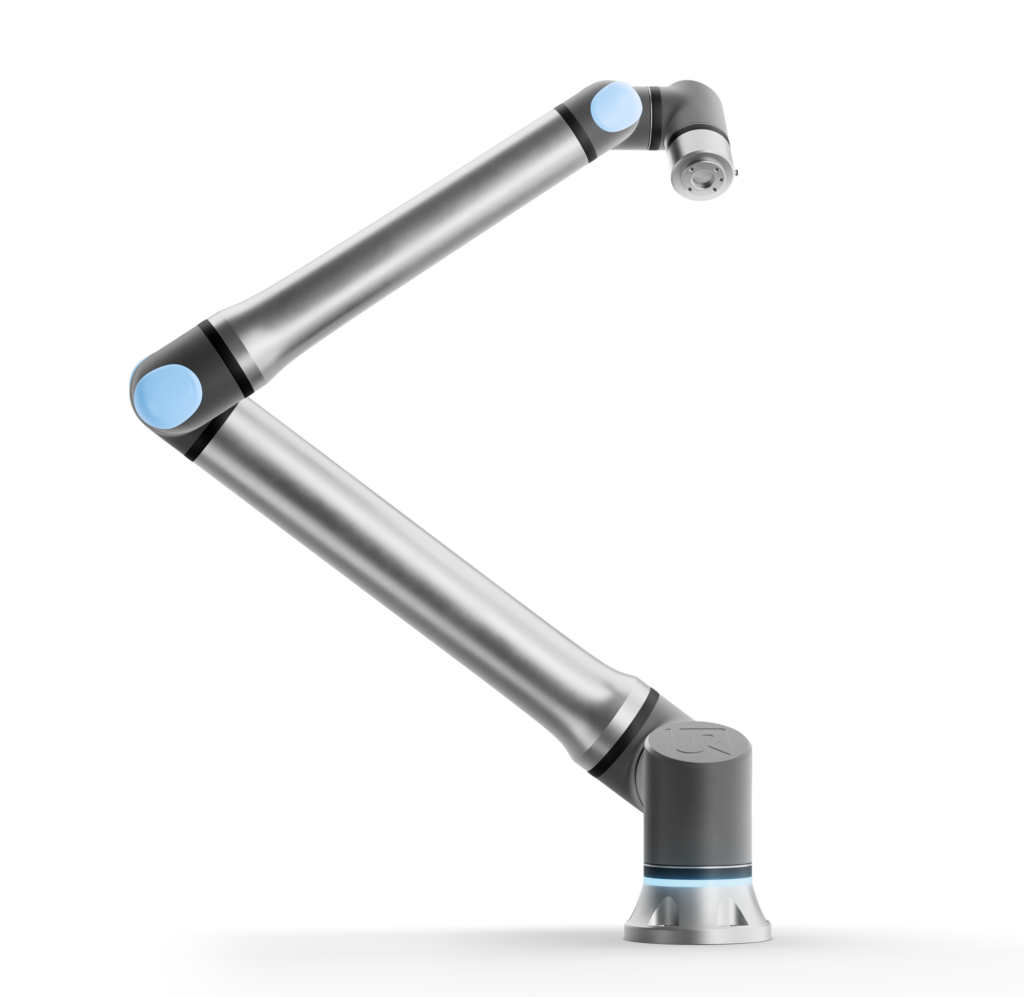

With the same 1750 mm (68.9 in) reach as the popular UR20 and a significantly slimmer profile, UR8 Long combines reach, stability and precision in a rugged, compact, lightweight form, featuring an 8 kg (17.6 lbs) payload. This makes it ideal for space-constrained setups and industrial tasks, from complex weldments to precision dunnage picking and flexible multi-point inspections.

Advanced technology for synchronised robot motion, intuitive programming and inverted mounting

UR8 Long runs with both PolyScope 5 and PolyScope X, UR’s industry-leading software platform, and can be extended with MotionPlus - UR’s new advanced motion control technology that allows for ease of integration with linear axis, rotary positioners and rotary turntables for precise control, smoother trajectories, and consistent accuracy.

Combined with UR’s upgraded freedrive capabilities, users can manually guide the arm with precision and ease - making lead-to-teach programming more intuitive and enabling quick, ergonomic setup even on complex parts, all without the need for layered interfaces or external tools. UR8 Long’s lighter mass - 30% less than the UR20 - and compact wrist design also makes it perfect for mounting on gantries, rails, or overhead systems, where external axes can operate more efficiently.