Introducing a game-changer

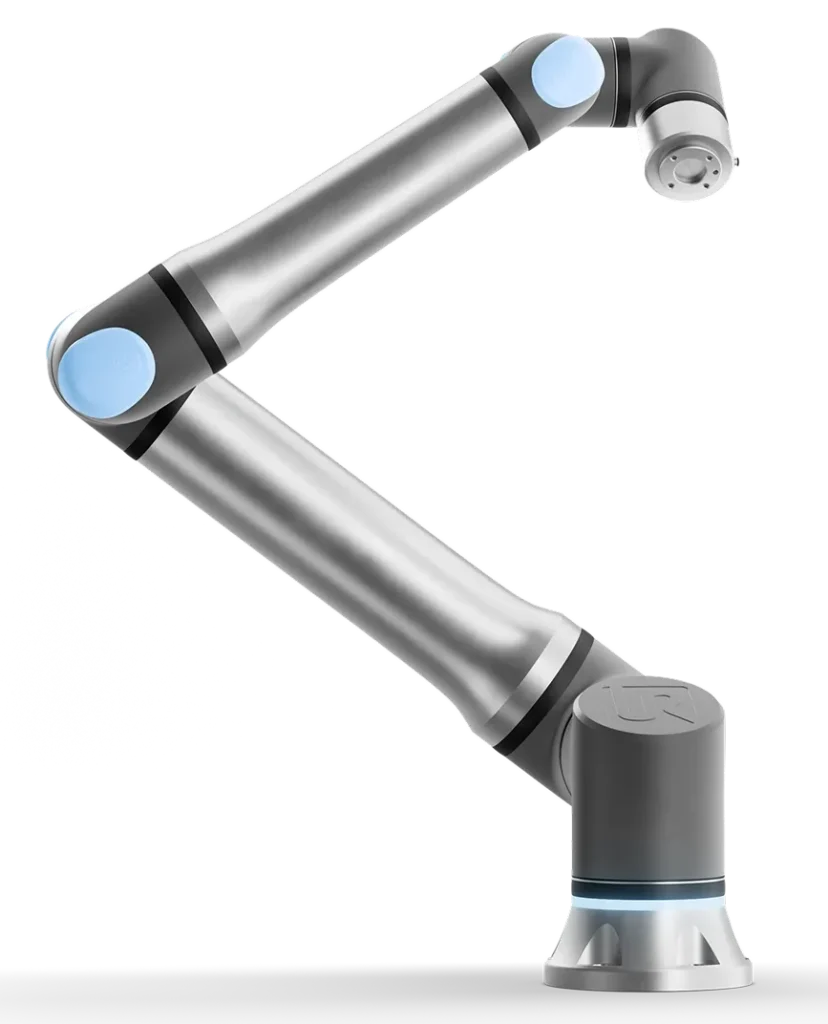

UR15 is the newest member of the UR series exceeding expectations in the most popular payload and reach.

It’s lightweight, weighing only 40.7 kg / 89.7 lbs, yet prodigiously strong. With a payload capacity of up to 17.5 kg / 38.8 lbs, UR15 breezes through intensive workloads. Its 1300 mm maximum reach aligned with its increased payload capacity makes the UR15 a unique product within the market granting speed and dependability that fits a variety of environments. The lightweight design and small footprint of the UR15 allows it to be quickly and effectively deployed and redeployed across a variety of work cells delivering maximum operating time.

UR15 brings a new era of flexible automation. As a smarter, faster, and more agile collaborative robot available in the market, UR15 is ready to help you transform your business.

Engineered for performance, designed for flexibility

UR15 delivers speed and precision wherever you need it. Designed to perform heavy-duty tasks at a level of performance never seen before.

It comes with excellence in Cleanroom, UL 1740, and TÜV certification, and it is always ready for collaboration.

It’s smartly designed with seamless wipe-down capability, so it suits environments with tight cleanliness demands.

UR15 removes the heavy lifting and repetitive motions in symbiotic collaboration with your workforce. Freed from repetitive tasks, workers can focus on innovation and higher value work, accelerating career development and elevating human ingenuity.

UR15 is powered by PolyScope X, our industry-leading software – and is ready to be supercharged with AI to enable seamless integration and unmatched usability.

Just as all our cobots, UR15 Is driven by our robust UR+ ecosystem, which allows customization and choice and opens the doors to limitless innovation.

Looking to automate demanding tasks without the complexity of traditional industrial robots?

The UR15 is ready to take on:

✅ Palletising: delivering a great payload-reach ratio, the UR15 is the perfect solution for handling your end-of-line palletising tasks.

✅ Machine tending: with an up to 17.5 kg payload capacity and fast wrist design, UR15 can lift heavier workpieces or multiples grippers to maximise door open efficiency and lower cycle times.

✅ Mobile applications: thanks to its lightweight design, it can be mounted on AMRs for maximum flexibility across your factory floor.

Want to see how the UR15 can speed up your operations and boost your productivity?

Get in contact with the Olympus Team today.