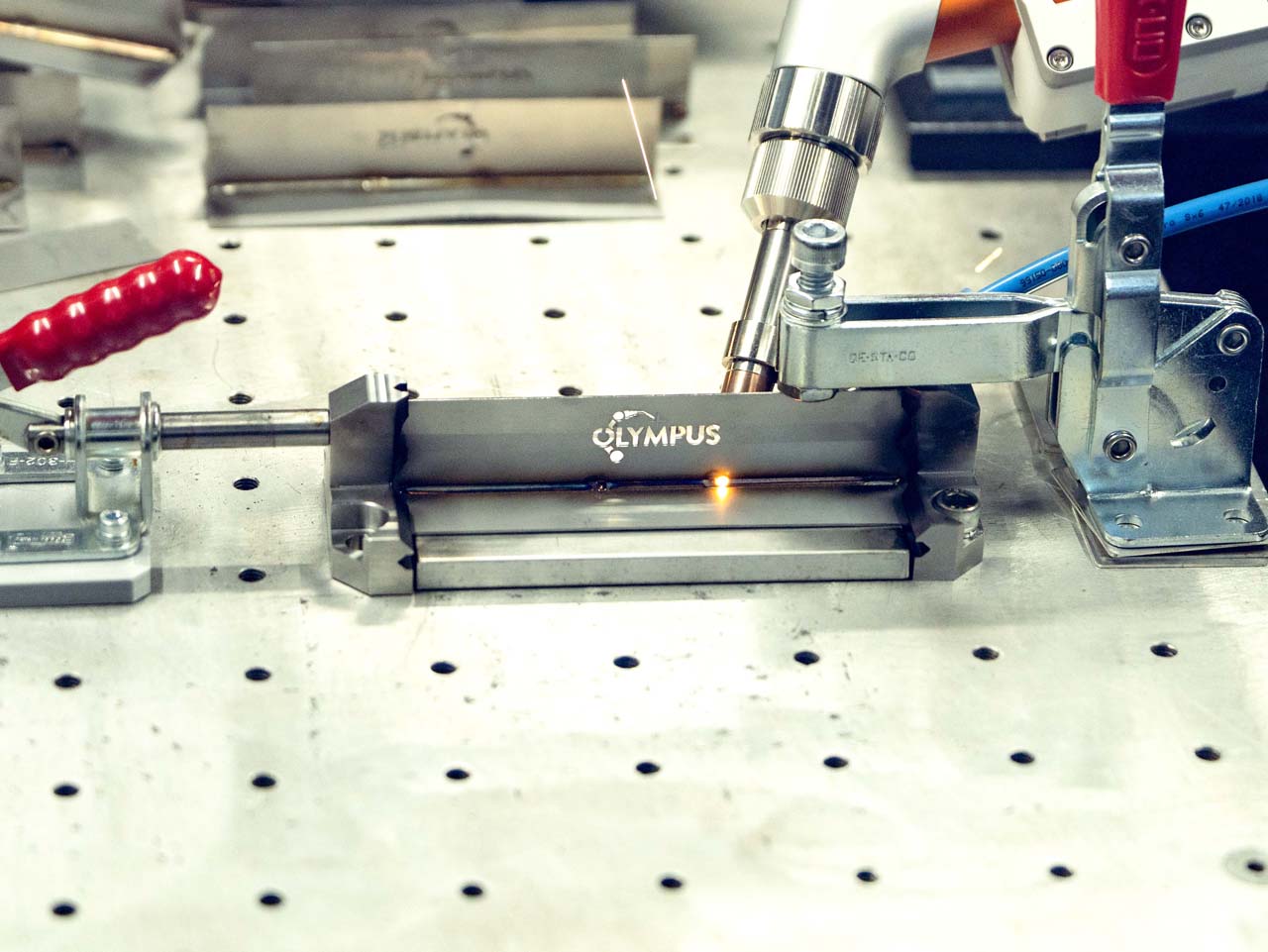

Olympus Technologies supports manufacturers by designing and delivering robotic and cobot solutions that work within existing production environments. This includes integrating robotic cells with current systems, validating performance through simulation, and ensuring safety and compliance from day one.

Integrating robots into an existing production line is no longer an emerging concept. For many manufacturers, it is a practical response to rising labour costs, increasing quality expectations, and the pressure to maintain productivity with fewer resources.

The challenge is not whether robotic automation works. The challenge is how to integrate robots, particularly collaborative robots, into existing production environments without disrupting output, compromising safety, or introducing unnecessary complexity.

This article explores how manufacturers approach robotic integration successfully, where cobots fit best, and how working with an experienced robotic integrator reduces risk from concept through to operation.

Why Manufacturers Are Turning to Cobots and Robotic Automation

Robotic systems are increasingly used to perform repetitive tasks that limit productivity or place strain on human operators. Cobots, in particular, have become a practical entry point for automation due to their flexibility, smaller footprint, and ability to work alongside human workers.

Common drivers for robotic automation include:

- Increasing productivity while maintaining consistent quality

- Reducing material waste and variation

- Managing labour costs without removing critical human expertise

- Improving safety on the production floor

- Supporting scalable solutions that can evolve with production needs

For many manufacturers, cobots offer a way to introduce automation without fully redesigning an existing production line.

The Real Risk Is Not Automation, It Is Poor Integration

Automation projects fail when robots are introduced without a clear understanding of existing systems, production flow, or human interaction.

Typical integration challenges include:

- Disruption to production during installation

- Incompatibility with existing PLCs, CNC machines, or safety systems

- Over reliance on human intervention to keep systems running

- Unrealistic assumptions around speed and cycle time

- Safety systems that restrict output rather than enabling smooth operation

This is where the role of an experienced robotic integrator becomes critical. Integration is not about installing robots. It is about designing systems that work reliably within real production constraints.

How Cobots Fit Into Existing Production Lines

Cobots are particularly effective in environments where space is limited, product variation is high, or human operators and robots need to share tasks.

Successful cobot integration starts with understanding the existing production environment, including:

- Current production needs and throughput targets

- Existing production line controls and software

- Tasks performed by human workers that are repetitive or ergonomically challenging

- Safety standards and compliance requirements

- Opportunities to minimise downtime during deployment

By integrating cobots around existing systems rather than replacing them, manufacturers can achieve seamless integration with minimal disruption.

Where Cobots and Industrial Robots Deliver the Fastest Value

Not every task benefits equally from automation. The strongest returns are typically seen where robots perform repetitive tasks with high consistency requirements.

These include:

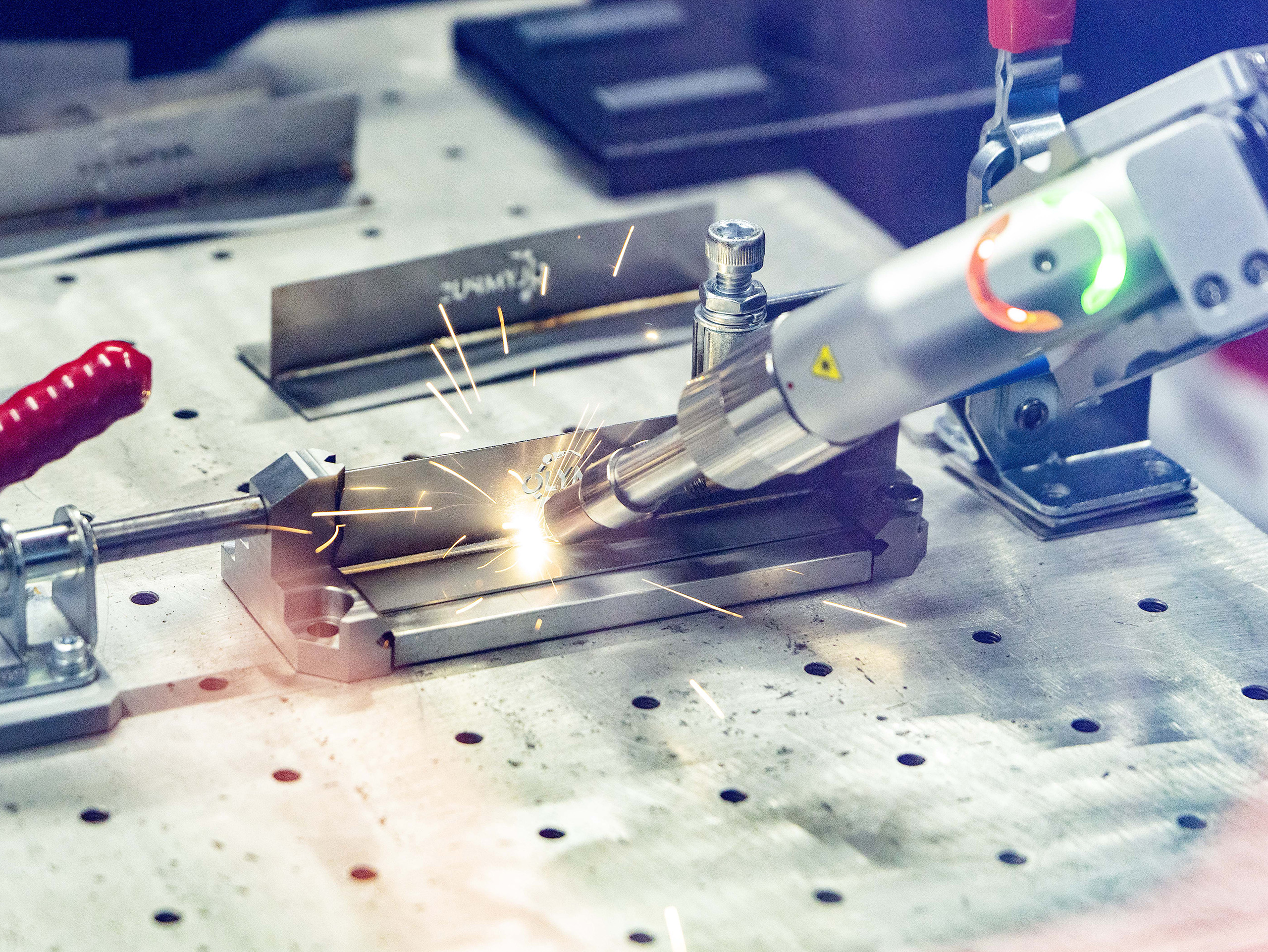

- CNC machine tending and automated loading and unloading

- Pick and place operations across multiple product variants

- Material handling between production stations

- Palletising and depalletising in constrained spaces

- Vision based quality control and inspection

In these applications, cobots and industrial robots improve speed, ensure consistent output, and reduce reliance on manual handling while allowing human labour to be redeployed to higher value activities.

The Importance of Simulation and Validation

Modern robotic integration relies heavily on simulation software to reduce risk before deployment.

Simulation allows manufacturers to:

- Validate cycle times and productivity assumptions

- Test cobot reach, speed, and task sequencing

- Design safety systems that protect people without limiting performance

- Identify bottlenecks within the production flow

- Reduce the likelihood of unplanned downtime during commissioning

This step is particularly important when integrating new robots into older equipment or complex existing production lines.

Safety, Human Interaction, and Compliance

Cobots are often chosen for their advanced safety features, including torque feedback and speed monitoring. However, ensuring safety still requires careful system level design.

Effective integration balances:

- Compliance with relevant safety standards

- Protection of human operators

- Maintaining productivity and smooth operation

When safety systems are properly integrated, cobots become a practical tool for intelligent automation rather than a constraint on production.

Where Olympus Technologies Fits In

For manufacturers exploring cobots or broader robotic automation, the difference between success and disruption often comes down to integration expertise.

Rather than pushing a specific robot or technology, the focus is on delivering systems that perform tasks reliably, minimise downtime, and provide long term benefits across productivity, quality control, and cost management.

Long Term Value Beyond the Initial Investment

While robotic integration involves an initial investment, the long term benefits often extend well beyond labour savings.

Well integrated cobot systems support:

- Reduced material waste and improved product quality

- Predictive maintenance and fewer production interruptions

- Software updates and adaptability as production changes

- Scalable automation that grows with manufacturing demand

This flexibility is what allows many manufacturers to stay ahead as new technologies and production requirements emerge.

Final Thoughts

Integrating robots without disrupting production is achievable when automation is approached strategically. Cobots offer a flexible, low disruption route into automation, but only when supported by careful planning, simulation, and experienced integration.

For manufacturers considering cobots or robotic automation, the key is not simply choosing the right robot, but choosing the right integration partner to ensure seamless integration with existing systems and people.

Frequently Asked Questions About Robotic and Cobot Integration

What is robotic integration in manufacturing?

Robotic integration in manufacturing involves connecting robots, sensors, vision systems, safety systems, and software into a single coordinated production system. The goal is to ensure robots operate reliably alongside existing machines and human workers, improving speed, quality, and uptime without disrupting production.

What is the difference between cobot integration and industrial robot integration?

Cobot integration focuses on safely embedding collaborative robots into shared workspaces, especially in small or medium sized factories where humans and robots work side by side. Industrial robot system integration connects high payload, high precision robots with other equipment for heavy duty tasks such as welding, palletising, or machine loading.

How do you integrate robots without disrupting an existing production line?

Successful integration relies on careful planning, simulation, and phased deployment. Robots are typically tested virtually using simulation software and digital twins, then introduced in stages to minimise downtime. Manual workarounds are often planned to keep the rest of the line operational during installation.

What safety standards apply to robotic integration?

Industrial and collaborative robot integrations must comply with standards such as ISO 10218 1, ISO 10218 2, and ISO TS 15066. Standardised safety protocols include emergency stops, light curtains, presence detecting sensors, and clearly defined safety zones integrated into existing line controls early in the project.

Can robots be retrofitted to older machines and software?

Yes. Robots can be retrofitted to existing machines through I O adapters, communication modules, and middleware. AI enabled retrofitting now allows robots to integrate with older equipment with minimal structural modification, making automation viable even in legacy production environments.