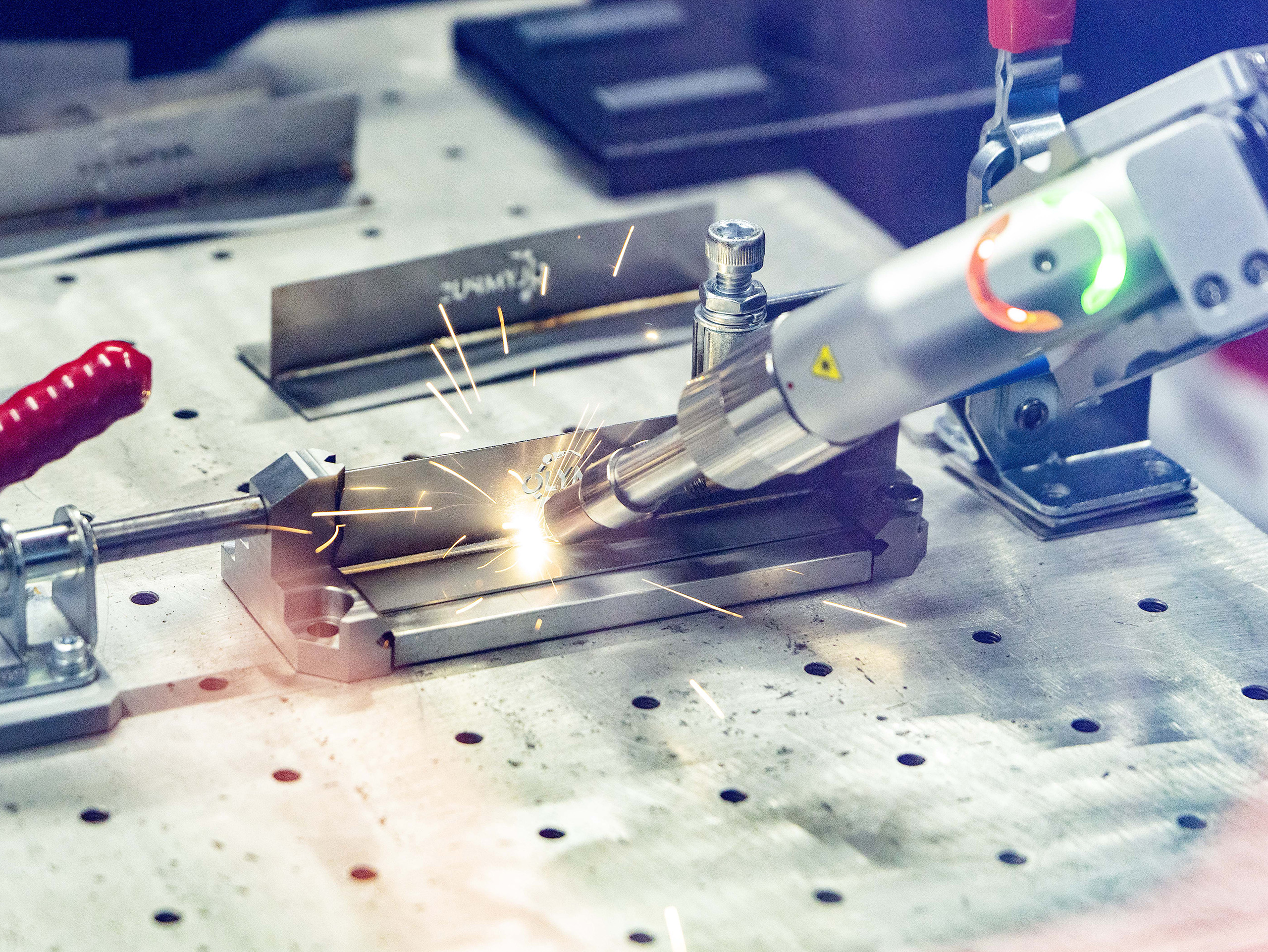

Reduce scrap, rework, and warranty risk with closed-loop robotic laser welding and inline inspection designed for stable, defect-free production.

Laser welding is widely adopted across medical device manufacturing, automotive, and high-precision industrial applications because it enables high speed joining with minimal distortion. However, unlike traditional welding methods, laser welding is far less forgiving of variation. Small changes in joint geometry, surface condition, shielding gas flow, or laser power can quickly lead to weld defects that compromise structural integrity and product quality.

In practice, most laser welding defects are not caused by the laser technology itself. They are caused by uncontrolled variation. Automation addresses this by making the welding process repeatable, measurable, and stable.

Why Laser Welding Defects Happen:

Laser welding relies on a highly concentrated laser beam to melt the base metal and form a controlled weld pool. The process delivers high energy density into a small weld zone, which enables fast welding speed and low heat input but also narrows the process window.

Most weld defects arise from a small number of controllable factors:

- Fit-up and joint geometry variation

- Surface contamination or oxide layers on the metal surface

- Inappropriate shielding gas or unstable gas flow

- Parameter drift such as fluctuating laser power or incorrect focus

- Motion or beam alignment errors at high welding speed

Automation prevents defects by controlling these variables and detecting deviation before poor weld quality reaches the customer.

Mini CTA: Share photos of your weld defect and joint design and we will identify likely root causes.

The Most Common Laser Welding Defects

The following are the most common welding defects seen in laser welding systems across various industries.

- Lack of fusion or insufficient penetration depth

- Porosity caused by trapped gas in the molten metal

- Undercut or melt collapse at the weld bead edge

- Cracking, including hot cracking and solidification cracking

- Spatter and metal ejection from an unstable molten pool

- Oxidation or discolouration of the weld surface

- Keyhole instability or humping at fast welding speed

- Off-seam welds caused by improper beam alignment

- Burn-through in thin sections from excessive heat input

- Inconsistent weld bead width or weld shape

Common defects at a glance

| Defect | Typical symptom | Common root causes | Fast checks |

|---|---|---|---|

| Lack of fusion | Shallow weld seam | Low laser power, excessive welding speed | Macro section |

| Porosity | Gas pores | Shielding gas problems, surface contamination | Visual + trends |

| Cracking | Fine surface cracks | High thermal stress, wide solidification temperature range | Sampling |

| Oxidation | Colour change | Inadequate shielding gas flow | Vision check |

| Off-seam weld | Misaligned bead | Improper beam alignment | Seam position |

Root Causes You Can Actually Control

Joint Preparation and Surface Contamination

Laser welding is extremely sensitive to surface condition. Oils, moisture, oxide layers, and coatings all affect laser absorption and molten pool stability. Even parts that appear clean can introduce defects if workpiece surface preparation is inconsistent.

Automation helps enforce cleaning standards and detect contamination-related variation.

Fit-Up and Gap Variation

Small changes in gap size have a disproportionate effect on penetration depth and weld quality in laser welding. Excessive gap or inconsistent joint geometry leads to lack of fusion or excessive heat input as operators attempt to compensate.

Robotic fixturing and controlled clamping reduce variation that manual methods cannot.

Shielding Gas Issues

Appropriate shielding gas selection, nozzle positioning, and stable gas flow are essential. Turbulent flow, cross-drafts, or incorrect gas composition can cause oxidation, porosity, and reduced corrosion resistance.

Automated systems maintain consistent shielding gas flow and monitor deviations.

Parameter Drift and Setup Inconsistency

Laser parameters such as power, focus position, welding speed, and filler material (when used) must remain stable. Fluctuating laser power or incorrect recipes lead directly to weld defects.

Automation locks parameters and prevents unauthorised changes.

Motion and Beam Alignment Problems

At high welding speed, small robot path errors translate into large quality issues. Improper beam paths, TCP drift, or inconsistent stand-off distance can push the laser beam off the weld joint.

Robotic motion control and calibration routines address this systematically.

How Automation Prevents Defects

Automation is not about adding complexity. It is about removing variability.

Consistent Motion Control and Fixturing

Robotic systems deliver repeatable motion profiles with controlled acceleration, corner behaviour, and stable approach and exit. Combined with proper fixturing, this reduces gap variation and stabilises the molten pool.

Seam Tracking and Vision Guidance

Automated vision systems track the weld joint in real time and keep the laser beam aligned, even when parts vary slightly. This is especially valuable when fixtures cannot fully constrain variability.

Closed-Loop Parameter Control

Automation enforces recipe control and can adjust parameters within defined limits when conditions change. This prevents defects caused by excessive laser power, insufficient heat input, or operator error.

Inline Inspection and Monitoring

Inline inspection detects problems early rather than relying on downstream inspection.

- Vision inspection checks weld bead width, weld shape, spatter, and seam position

- Process monitoring tracks energy delivery, weld pool stability, and trends

- Automatic reject routing prevents defective parts entering downstream processes

Prevention methods compared

| Prevention method | Defects it prevents | What it needs | Typical limitation |

|---|---|---|---|

| Motion control | Off-seam, undercut | Stable fixturing | Upfront design |

| Seam tracking | Misalignment | Vision calibration | Not needed for all parts |

| Closed-loop control | Fusion defects | Sensors and logic | Narrow control band |

| Inline inspection | Appearance defects | Lighting stability | Surface dependent |

Defect-by-Defect: Prevention Playbook

Lack of Fusion or Low Penetration

Prevention focuses on fit-up control, optimised laser power, correct focus position, and controlled welding speed. Seam tracking ensures the laser beam stays on the weld joint.

Detection relies on monitoring penetration-related trends and periodic macro checks.

Porosity

Porosity is driven by surface contamination, shielding gas flow issues, and unstable molten metal.

Automation enforces cleaning procedures, stabilises shielding gas selection and flow, and flags process drift before porosity becomes visible.

Cracking

Cracking is common in high carbon steels and high strength steels with wide solidification temperature ranges.

Prevention requires careful welding energy control, joint design review, and sometimes filler metal selection. Consistency is critical.

Oxidation and Discolouration

Oxidation results from inadequate shielding gas coverage or turbulent flow.

Vision inspection detects colour changes in the weld zone, while automation stabilises gas delivery.

Off-Seam Welds

Off-seam welds result from improper beam alignment or motion error.

Seam tracking, robot calibration, and improved fixturing prevent the issue entirely.

Defect response summary

| Defect | Prevent | Detect | Fix fast |

|---|---|---|---|

| Lack of fusion | Fit-up + power | Macro + trends | Reduce speed |

| Porosity | Cleaning + gas | Monitoring | Adjust flow |

| Cracking | Heat strategy | Sampling | Parameter tuning |

| Oxidation | Gas control | Vision | Improve coverage |

| Misalignment | Seam tracking | Vision | Re-calibrate |

Special Materials Where Automation Matters Most

High-Strength Steels

High strength steels have narrow process windows and are sensitive to thermal stress. Automation ensures consistent heat input and repeatable weld shape.

Aluminium and Reflective Materials

High thermal conductivity and reflectivity challenge laser energy absorption. Stable beam quality, fiber lasers, and precise parameter control reduce surprises.

| Material | Common defect risks | Key controls | Automation add-ons |

|---|---|---|---|

| High strength steel | Cracking | Heat control | Monitoring |

| Aluminium | Porosity | Gas stability | Vision |

| Reflective metals | Fusion loss | Energy density | Closed-loop |

Laser vs Arc Welding for Defect Risk

Laser welding reduces defects when distortion control, high precision, and repeatability matter most. Arc welding may be more forgiving for large gaps, dirty environments, or thick sections where precision is lower.

This honesty is critical to selecting the right welding methods.

How We Reduce Defects on Your Line

Step 1: Weld Defect Audit

Review welding process data, joint geometry, shielding gas, laser parameters, and historical failure modes.

Step 2: Trials and Acceptance Criteria

Define defect-free laser welds using measurable targets for penetration, appearance, and structural integrity.

Step 3: Cell Upgrade or Turnkey Automation

Introduce fixturing, seam tracking, inline inspection, and recipe control as required.

Step 4: Validation and Handover

Complete FAT, SAT, SOPs, training, and maintenance planning.

CTA: Book a Weld Quality Audit.

ROI: What Better Quality Is Worth

Reducing weld defects has direct financial impact.

- Lower scrap and rework

- Faster QA release

- Reduced downtime from troubleshooting

- Fewer customer complaints and warranty claims

| Cost of poor quality | Current baseline | Target | Annual saving |

|---|---|---|---|

| Scrap | % | Reduced | Estimated |

| Rework | Hours | Reduced | Estimated |

| Downtime | Events | Reduced | Estimated |

Frequently Asked Questions

Do we need seam tracking?

Only when part variation or fixturing limits alignment accuracy.

Can monitoring detect porosity or cracking?

It detects conditions that cause them, not every defect directly.

How clean is clean enough?

Cleaner than most traditional welding processes require.

What shielding gas should we use?

It depends on material and joint design.

How long does a quality retrofit take?

Typically phased to minimise disruption.