What are Collaborative Robots and Grippers?

Collaborative robots, or cobots, are automation tools designed to work safely alongside humans, boosting efficiency and productivity in manufacturing and other industries.

Central to their functionality are grippers, components that mimic the human hand's ability to grasp and manipulate objects.

Cobots and their grippers perform different tasks, such as assembly, handling tasks, inspection, and packaging, with precision, reliability, and adaptability.

Types of Cobot Grippers

- Electric Grippers: Suitable for complex tasks, electric grippers offer precise control, adjustable gripping force, and the ability to handle objects of varying weight and geometries. Electric Grippers also avoid the need for air supply or additional cables.

- Pneumatic Grippers: Operated by compressed air, pneumatic grippers provide high gripping force suitable for robust applications requiring speed and reliability, such as manufacturing assembly lines.

- Vacuum Grippers: Utilise vacuum pressure to lift and handle porous materials or objects with undefined positions, making them highly versatile in automation scenarios.

- Magnetic Grippers: Employ magnetic force to securely grip metallic objects, beneficial in environments requiring high gripping force and swift operation.

Choosing the Right Cobot Gripper

Selecting the ideal cobot gripper depends on several key factors:

- Object Material and Weight: Evaluate the materials and weight of the objects the robot will handle.

- Required Gripping Force: Consider the necessary gripping, closing force, and opening force for the application.

- Precision and Flexibility: Assess the required precision for handling tasks, considering if the gripper must manage objects with various shapes and sizes.

- Integration and Compatibility: Ensure the gripper's seamless integration with your cobot and existing system.

End of Arm Tooling and End Effectors

End of arm tooling refers to devices, such as grippers and other end effectors, mounted on the cobot's arm. End effectors interact directly with objects and the environment, including sensors, cameras, welding tools, and grippers.

Grippers, as end effectors, directly influence a cobot's ability to execute precise handling and assembly tasks, significantly enhancing automation efficiency.

Cobot Software and Integration

Advanced cobot software provides user-friendly programming and seamless integration capabilities. Grippers and other end effectors can easily communicate with the cobot's control system, enabling "Plug & Play" quick installation, efficient setup, and reduced time spent configuring tasks.

Benefits of Using Cobot Grippers

Integrating cobot grippers offers numerous advantages:

- Enhanced Efficiency: Improve productivity across diverse manufacturing processes.

- Precision and Accuracy: Grippers enhance positioning accuracy and gripping precision, critical in assembly and inspection tasks.

- Flexibility and Adaptability: Ability to handle various workpieces with different geometries and sizes.

- Long Service Life: Quality grippers offer durability, reducing maintenance requirements and enhancing overall equipment reliability.

Different Types of Applications

Cobot grippers excel in various applications:

- Assembly and Inspection: Tasks requiring high precision, accurate positioning, and adaptability.

- Packaging and Palletising: High gripping force and the capability to handle objects quickly and securely.

- Cleanroom and Hazardous Environments: Handling tasks where sealed grippers and specialised materials are required to maintain safety and cleanliness standards.

FAQs on Cobot Grippers and Automation Efficiency

1. What are cobot grippers, and why are they important?

Cobot grippers are specialised end effectors designed to enable collaborative robots to grip, lift, and manipulate objects in various handling tasks. They are essential for improving efficiency, precision, and automation in industries such as manufacturing, assembly, and logistics.

2. What are the different types of cobot grippers?

There are several types of cobot grippers, each suitable for different applications:

- Electric grippers - Provide precise gripping force, adjustable opening force and closing force, and are ideal for delicate workpieces.

- Pneumatic grippers - Powered by compressed air, offering high gripping force and fast operation, ideal for high-speed assembly lines.

- Vacuum grippers - Use vacuum pressure to lift and transport objects, making them effective for handling porous materials or objects with undefined positions.

3. How do I choose a suitable cobot gripper for my application?

When selecting a cobot gripper, consider:

- Gripping force - Ensure the gripper provides the right amount of force to securely hold the workpieces without damaging them.

- Weight and size of the object - The gripper must be strong enough to lift and handle objects of varying weight and dimensions.

- Precision and flexibility - Choose a gripper that can handle different types of workpieces with varying geometries.

- System compatibility - Ensure the gripper integrates with your robot control system and other arm tooling components.

4. What is the difference between electric grippers and pneumatic grippers?

- Electric grippers operate using electric motors, allowing precise control over gripping force, opening force, and closing force. They are energy-efficient and ideal for handling small, delicate objects.

- Pneumatic grippers are powered by compressed air, providing high gripping force and fast response times, making them suitable for heavy-duty applications.

5. How does gripping force affect cobot performance?

Gripping force determines how securely a gripper can hold an object. Too much force can damage fragile objects, while too little may cause workpieces to slip. The ideal gripping force depends on factors such as the weight, material, and shape of the object.

Conclusion

Cobot grippers play an essential role in collaborative robotics, enabling robots to perform numerous tasks requiring object handling with human-like precision and flexibility.

Choosing the suitable gripper involves evaluating factors like gripping force, precision, integration ease, and flexibility. By effectively integrating cobot grippers, industries significantly enhance productivity, efficiency, and operational capability.

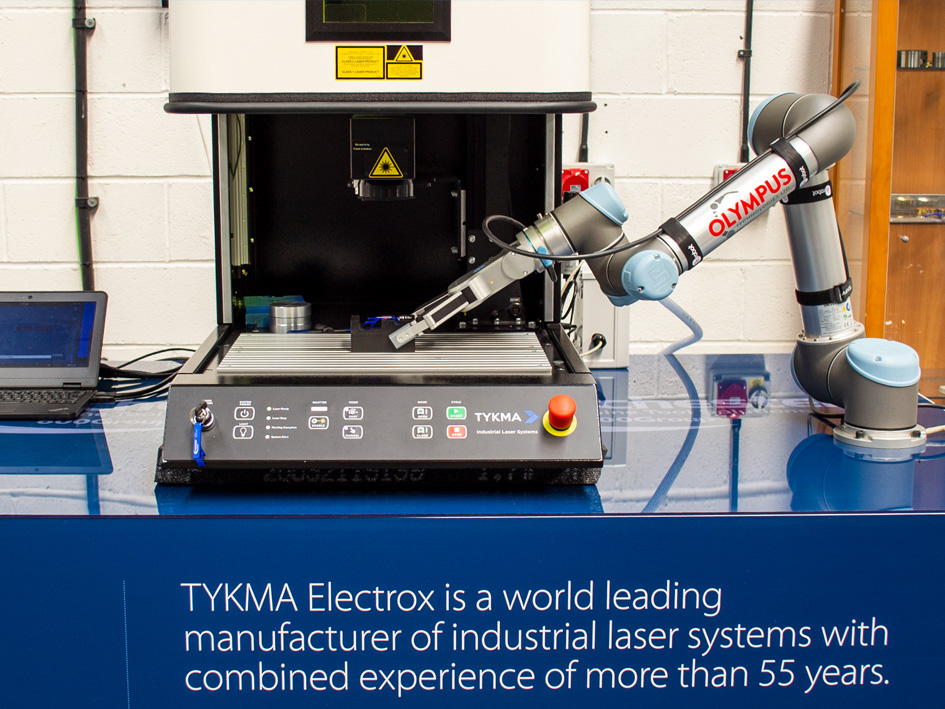

Here at Olympus Technologies we design and manufacture a range of standard and bespoke grippers and end of arm tooling for lifting and handling any component, in any industry - Find out more about our bespoke grippers here.