At Olympus Technologies, we know that robotic welding isn’t just about cutting-edge tech - it’s about solving real-world production headaches.

Whether you're battling rising labour costs, struggling to find experienced welders, or just looking to boost your output, our bespoke robotic welding systems are designed to deliver superior weld quality and seamless integration into your existing workflows.

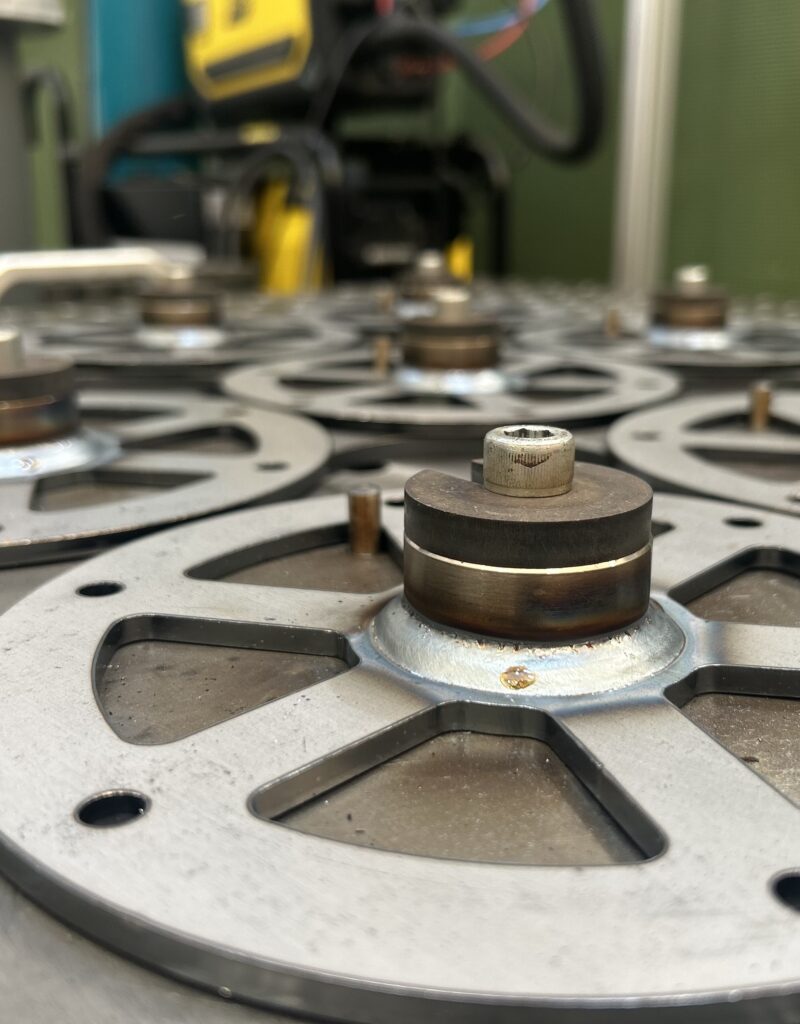

As a trusted cobot and robot integrator based in Huddersfield, we specialise in designing and integrating robotic solutions that automate repetitive welding tasks, allowing your skilled welders to focus on complex, high-value work.

With the American Welding Society estimating a need for over 320,000 new welding professionals by 2029, robotic welding technology has never been more vital for closing the skills gap [American Welding Society, 2023].

Precision Welding Means Consistent Weld Quality

Getting Welds Right, Every Time

Accuracy is everything when it comes to welding. That’s why our bespoke robotic welding systems are built to deliver consistent, defect-free welds across a wide range of applications. From robotic laser welding on thin-gauge electronics to arc welding for automotive frames, our solutions are all about repeatability.

Real-world example:

One welding robot can be programmed to precisely manage welding parameters like torch angle, travel speed, and heat input, reducing spatter and porosity while producing uniform welds with minimal distortion.

Why it matters:

High quality welds mean fewer reworks, reduced use of filler material, and more reliable metal components.

Increased Productivity with Automated Welding Processes

Let the Robots Handle the Heavy Lifting

When you're relying on manual welding alone, you're limited by human speed and stamina. But with robotic welding systems, your production process can run continuously - with minimal downtime.

Key benefits:

- Shorter weld cycles

- Reduced material handling

- Higher output without compromising on quality

For high-volume sectors like automotive manufacturing, this translates into serious gains in efficiency and cost savings.

Less Waste, More First-Time Accuracy

Smarter Welding, Cleaner Results

With traditional welding methods, it's easy to fall into the trap of overwelding, heat distortion, or misaligned weld paths. Our robotic systems are programmed to stick to exact specifications every time, ensuring consistent welds and reducing material waste.

What we reduce:

- Human error in positioning

- Inconsistent travel speed

- Costly reworks due to flawed joints

The result? A leaner, cleaner production environment with better first-pass yield and fewer calls to QA.

Making Welding Safer for Human Workers

Enhance Safety Without Sacrificing Skill

Let’s talk safety. Welding involves intense heat, molten metal, electric arc exposure, and shielding gas - all of which pose serious risks. Robotic welding not only reduces labour costs but also keeps human workers out of harm’s way.

What robotic welding offers:

- Reduced exposure to hazardous fumes and UV light

- Fewer repetitive tasks

- Opportunities for upskilling in robot programming and system monitoring

With our systems in place, your skilled welders can transition into more rewarding roles - enabling welders to supervise, troubleshoot, and optimise instead of just enduring repetitive tasks.

Tailored Robotic Welding Solutions for Your Industry

From Aerospace to Construction - We’ve Got You Covered

Every industry has its own welding quirks. That’s why we don’t believe in one-size-fits-all systems. Whether you’re tackling complex geometries or working with delicate thin materials, we’ll customise a robotic welding solution to suit your exact needs.

Industry-specific snapshot:

| Industry | Welding Method | Key Benefit |

|---|---|---|

| Automotive | MIG, spot welding | Fast, repeatable welds for high output |

| Aerospace | Laser welding | Pinpoint precision on thin alloys |

| Custom Fabrication | Robotic TIG or MIG | Flexible solutions for short runs |

Our expertise spans robotic systems for welding, machine tending, press brake operations, and more - perfect for automating both large-scale and bespoke manufacturing processes.

Conclusion: Welding Automation That Keeps You Ahead

Investing in robotic welding isn’t just about keeping up - it’s about getting ahead. Olympus Technologies helps you streamline your welding operations, reduce errors, and improve both safety and efficiency.

With our bespoke robotic welding systems, you get:

- Consistent weld quality

- Faster, more efficient production

- A safer workplace for your team

- Long-term savings across your manufacturing processes

Ready to future-proof your factory with a robotic welder that fits your business like a glove? Get in touch - we’ll help you find the perfect automated system for your welding applications.

FAQs About Robotic Welding and Automation

How do robotic welding systems help in ensuring consistent weld quality?

Robotic welding systems are programmed to follow precise weld paths and maintain consistent welding parameters such as torch angle, speed, and heat input. This eliminates human variability and ensures uniform welds every time - especially critical in industries where high standards are non-negotiable.

What’s the difference between robotic and manual welding?

Manual welding relies on human skill, which can vary based on fatigue, technique, or training. Robotic welding, on the other hand, uses automated systems to perform repeatable welds with high accuracy. It’s ideal for large-scale production where consistent quality is essential, while skilled welders can focus on more complex welding tasks.

What are arc welding robots used for?

Arc welding robots are commonly used in industries like automotive and construction to perform deep, reliable welds on structural components. These robots use an electric arc between an electrode and the base metal to melt and join materials with precision and speed.

Do I need special welding equipment for robotic welding?

Yes, robotic welding typically requires specialised welding equipment such as a welding torch mounted on a robot arm, a power supply, safety enclosures, and sometimes a shielding gas system - depending on the welding method being used (e.g., MIG, TIG, or laser).