Track every raw material input, lot number, and process step across your production line in real time, reducing recall risk, strengthening regulatory compliance, and enabling better quality decisions across the supply chain.

For many manufacturing companies, traceability has historically been treated as a downstream compliance requirement rather than a core production capability. Data is often captured late, manually, or inconsistently, leaving gaps between what happens on the shop floor and what is recorded in enterprise systems. When an issue arises, whether related to food safety, contamination risk, or customer quality complaints, those gaps become immediately visible.

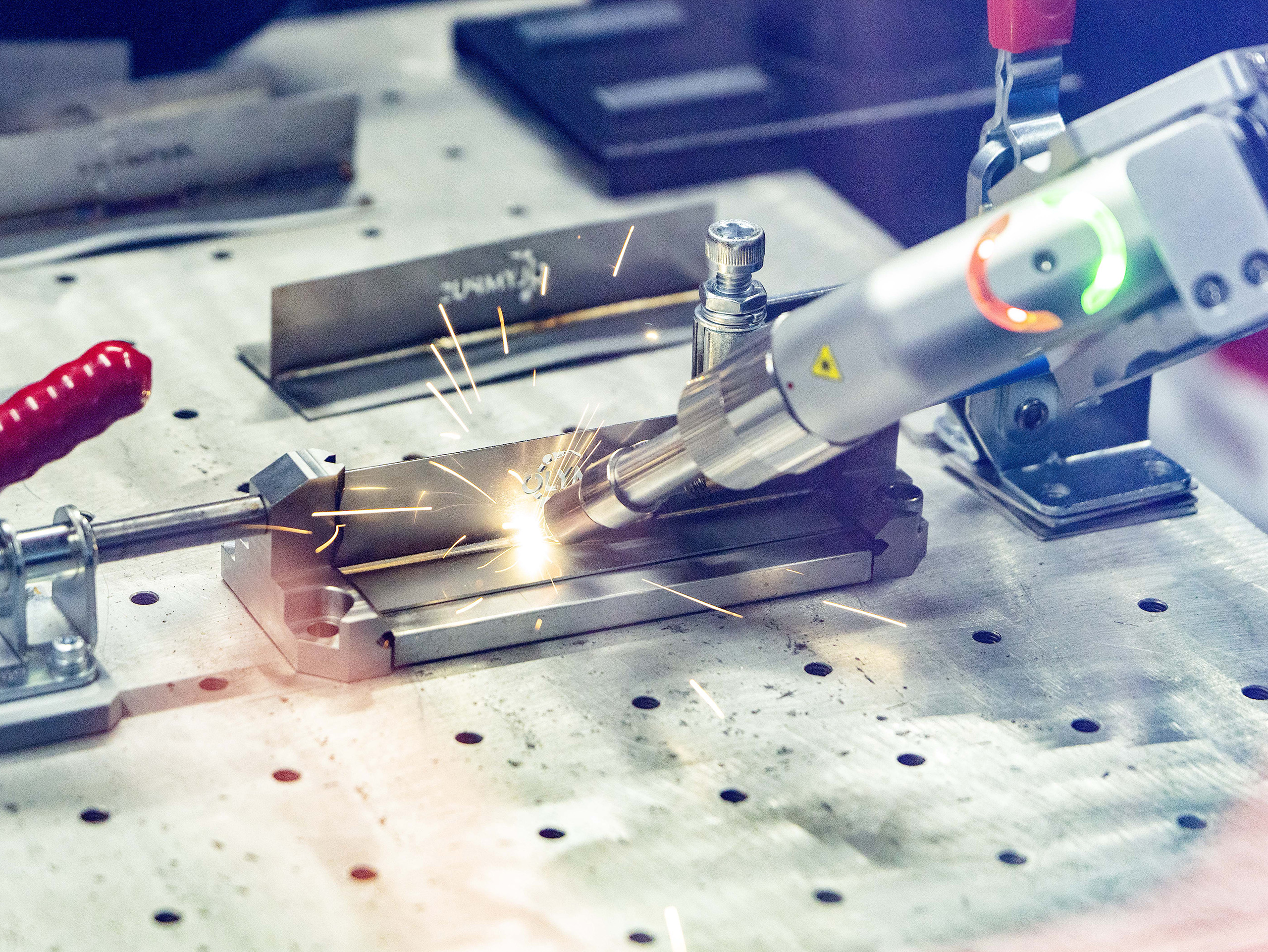

At Olympus Technologies, we see traceability as an operational discipline. By integrating collaborative robots, machine vision, and traceability systems directly into production processes, manufacturers can move from fragmented records to full, end to end traceability that is created automatically as products move through the line.

Why Traceability Breaks Down on Modern Production Lines

Most traceability failures are not caused by a lack of intent or investment. They arise because manual operations are still responsible for critical tracking points across the manufacturing process.

Handwritten records, inconsistent scanning, and manual label handling introduce risk at exactly the stages where accuracy matters most. Rework and repack processes often break the data chain entirely. Disconnected systems across production, packaging, and warehousing further fragment traceability, making audits time consuming and recalls difficult to execute with confidence.

For manufacturers producing food products or medical devices, these gaps increase contamination risk, reduce shelf life control, and expose the business to regulatory non compliance. The major benefit of robotics technology is that it removes discretion from these points and replaces it with enforced, repeatable verification.

What End-to-End Traceability Looks Like in Practice

True end-to-end traceability means that any finished product can be traced back through every stage of the manufacturing process and forward through the supply chain, using verified data captured at source.

This requires identity capture and verification at receiving, preservation of identity during processing, confirmation during packaging, and accurate aggregation during palletising and dispatch. Each step must be automatically recorded, time stamped, and linked to the correct lot number without reliance on manual input.

Olympus Technologies approaches traceability as a system design challenge, integrating robotics, vision systems, and enterprise data layers into a single traceability system that reflects how production actually runs on the shop floor.

Traceability events across the production lifecycle

| Production stage | What must be captured | Typical identifier | Common failure point | Robotics-led control |

|---|---|---|---|---|

| Receiving | Raw material inputs | Barcode, QR, RFID | Missed or incorrect scans | Automated scan and vision verification |

| Processing | Batch association | Lot number | Manual data entry | Robotic handling with event capture |

| Packaging | Label accuracy | Code, date, lot | Label mix ups | Vision inspection and reject routing |

| Palletising | Aggregation | Case to pallet | Incorrect builds | Automated pallet ID creation |

| Dispatch | Shipment verification | Pallet ID | Wrong load | Final robotic verification |

This structure is what enables full traceability across production lines and assembly lines, even in high mix or high throughput environments.

Where Robotics and Cobots Deliver the Most Traceability Value

Robotics delivers the greatest value where speed, variability, and manual handling undermine data integrity.

Receiving and Raw Material Handling

At intake, cobots and industrial robots equipped with machine vision automatically verify raw material inputs. Labels, codes, and markings are checked using barcode reading, OCR, RFID, or laser marking verification before materials enter production.

This protects food safety, supports quality assurance, and ensures compliance with industry standards from the first stage of the manufacturing process.

In-Process Tracking and Identity Preservation

Maintaining identity during production is one of the most difficult traceability challenges, particularly in complex or high mix environments.

Robotic systems preserve identity by controlling how materials move between stages. Cobots handle trays, bins, and components consistently, while vision systems verify correct routing and prevent cross contamination. Automated measurements are linked reminder to the traceability system, creating reliable, time stamped records.

This reduces human error and improves operational efficiencies across the shop floor.

Packaging, Labelling, and Code Verification

Packaging is often where traceability failures become visible to customers and regulators.

Robotics led verification ensures labels are present, correct, and readable. Vision systems inspect printed codes, lot numbers, and expiry dates, while laser marked identifiers are checked for permanence. Incorrect products are automatically rejected, with each decision recorded in the system.

For food production and medical device manufacturers, this stage is vital to meeting regulatory compliance and customer requirements.

Palletising, Aggregation, and Dispatch

At dispatch, robotics creates reliable aggregation from unit to case and case to pallet. Pallet IDs are created and verified automatically before wrapping and shipping.

This final verification step is essential for maintaining full traceability across the supply chain and enables faster, more accurate recall execution if required.

The Core Components of a Robotic Traceability Solution

A robust traceability solution is built from integrated components rather than standalone equipment.

| Component | Role in traceability | Why it matters |

|---|---|---|

| Robotics systems | Enforce consistent handling | Removes variability and manual error |

| Machine vision | Verify identity and quality | Ensures data accuracy at speed |

| Identification tech | Persist product identity | Supports shelf life and compliance |

| Data integration | Connect events to systems | Enables audit readiness and analytics |

Olympus Technologies specialises in integrating these components into cohesive systems that operate reliably in real production environments, including wet conditions, reflective packaging, and legacy equipment.

Compliance, Quality, and Audit Readiness

Auditors and regulators across food, medical device, and other regulated industries expect manufacturers to demonstrate clear, tamper resistant traceability aligned with regulations and industry standards.

Robotics reduces compliance risk by limiting manual operations, enforcing verification at critical points, and generating consistent digital records. Beyond audits, this improves quality control by providing reliable data for investigations, corrective actions, and continuous improvement.

Measurable Business Benefits Beyond Compliance

The benefits of robotics led traceability extend beyond passing audits.

Manufacturers typically achieve lower rework and quarantine costs, fewer customer complaints related to labelling or identification errors, improved operational efficiency, and stronger market confidence. Data analytics derived from traceability systems also support better decision making across production, quality, and supply chain operations.

How Olympus Technologies Delivers Traceability With Robotics

Our approach begins with mapping how traceability currently operates across your production line and identifying where data integrity breaks down.

We then design robotics led solutions that introduce verification, tracking, and integration at the right stages, without disrupting production. Pilot deployments validate accuracy and performance before wider rollout, supported by documented procedures, maintenance planning, and long term support.

This ensures traceability systems are scalable, compliant, and future ready.

Next Step: Traceability Assessment

If you are looking to improve traceability across your entire production line, the first step is understanding how your current system performs in practice.

A traceability assessment reviews product type, packaging, production speed, identification methods, and existing failure points. From there, a clear roadmap can be developed.

Book a Traceability Assessment or Get a Budgetary Proposal