Automation is no longer reserved for large manufacturers with high-speed production lines. Small and medium sized enterprises (SMEs) are adopting robotic systems to address labour shortages, improve workplace safety, and keep up with changing market demands. From robotic machine tending to robotic case packing, these technologies are becoming a practical solution for medium sized enterprises seeking a competitive advantage across various industries.

This guide explores where automation has the greatest impact, how SMEs can implement robotic arms effectively, and what kind of return on investment to expect.

1. Robotic Machine Tending for SMEs: Is It Worth the Investment?

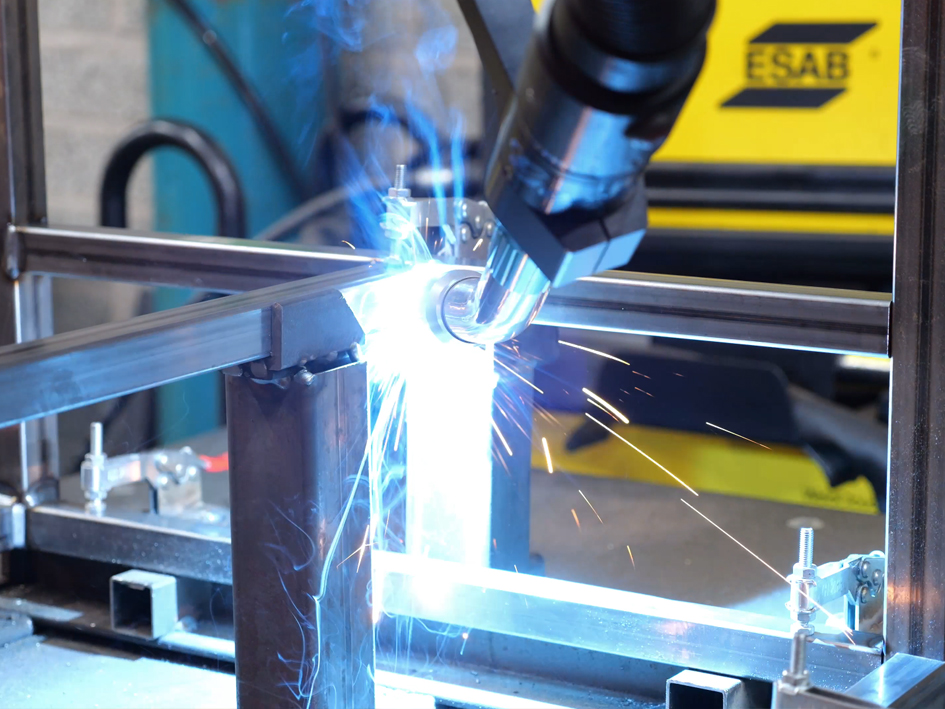

Machine tending involves loading raw materials into machines, monitoring cycles, and unloading finished components. Traditionally performed by human operators, these physically demanding tasks expose the human workforce to hazardous tasks and inconsistent output. Robotic machine tending uses robotic arms and intuitive programming to perform tasks with high accuracy and consistent quality.

Applications for SMEs include:

- CNC machine tending where robots load billets and remove finished parts.

- Injection molding machines that require handling hot or heavy moulded components.

- Press brakes where robots move metal sheets with precision, reducing risk for human workers.

For SMEs, robotic machine tending robots automate repetitive tasks, fill gaps caused by recruitment challenges, and boost productivity. Collaborative robots equipped with force limiting technology provide a cost effective solution that works safely in tight spaces without extensive safety caging.

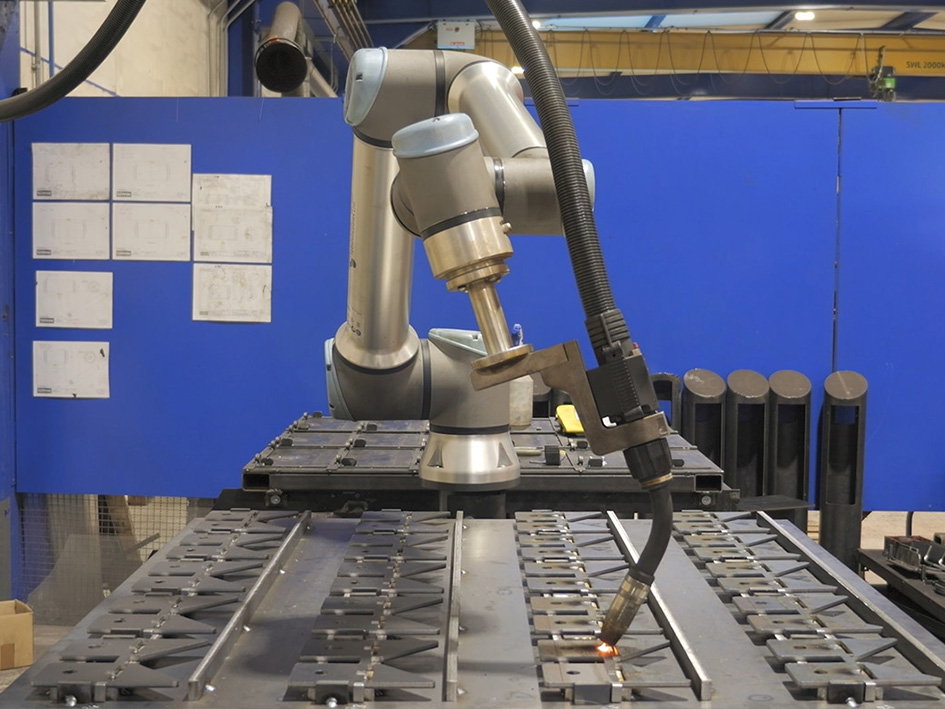

While traditional industrial robots once demanded significant investment, today’s collaborative robots (such as Universal Robots) make automation accessible. SMEs can begin with pilot projects, spread out the initial investment, and scale as confidence grows. Financing options help shorten the payback period, making robotic systems a practical solution rather than a luxury.

2. Press Brake Automation: Boosting Safety and Efficiency

Press brakes are vital in metal fabrication but create risks when operated manually. Handling heavy sheets exposes human workers to repetitive stress injuries and potential accidents.

Safety improvements with press brake robots:

- Collaborative robots remove the need for human operators to position metal sheets.

- Force limiting technology minimises accidents, while intuitive programming reduces complex programming errors.

- Automating repetitive, hazardous tasks improves workplace safety and preserves the human workforce.

Efficiency gains include:

- Robots maintain consistent quality and reduce rework.

- Robotic machine tending shortens cycle time and increases uptime.

- Compact footprint designs allow robotic arms to fit into tight spaces on the shop floor.

A medium sized enterprise producing high mix low volume sheet metal parts adopted a robotic arm for press brakes. Within months, they enhanced productivity, improved workplace safety, and gained a measurable competitive advantage over businesses still relying on traditional robots.

3. Press Brake Robot Integration: Step-by-Step Checklist

Integrating robotic arms into press brake operations requires planning. SMEs benefit from a structured approach:

- Pre-integration planning: Evaluate the shop floor layout, payload capacity, and safety requirements.

- Choosing the right robot and tooling: Decide between collaborative robots and traditional industrial robots depending on cycle time, material handling needs, and budget.

- Software and programming: Intuitive programming reduces complex programming barriers and provides unparalleled flexibility.

- Training and change management: Human workers must learn to work alongside robotic systems to ensure seamless integration.

- Testing, optimisation, and scaling: Pilot projects validate performance before scaling across multiple machines.

By following this checklist, SMEs can implement robotic machine tending with minimal disruption and gain long-term benefits in increased productivity and consistent quality.

4. ROI of Robotic Case Packing in Short-Run Production

Historically, automating repetitive packing tasks for short production runs was challenging. High mix, low volume production required frequent changeovers, making automation appear costly.

Today, robotic systems equipped with end of arm tooling and intuitive programming handle low volume production efficiently. This makes robotic case packing a cost effective solution for SMEs facing labour shortages and recruitment challenges.

ROI framework:

| Production Run Length | Labour Savings | Payback Timeline | Notes |

|---|---|---|---|

| 2–4 weeks | Moderate | 12–18 months | Effective for addressing labor shortages and variable demand |

| 1–3 months | High | 8–12 months | Strong ROI from automating repetitive tasks |

| Continuous | Very high | 6–9 months | Increased productivity and consistent quality |

By automating repetitive case packing, SMEs reduce reliance on human operators, improve workplace safety, and increase production output across production lines.

5. Automated Case Packing: Top Mistakes to Avoid

When adopting palletising robots or case packing automation, SMEs sometimes overlook critical factors. Avoiding these pitfalls makes implementation smoother:

- Ignoring product variation and underestimating the flexibility needed for high mix low volume tasks.

- Choosing unsuitable end of arm tooling for specific tasks such as fragile goods or irregular packaging.

- Skipping operator training, which prevents seamless integration with new tasks.

- Overlooking total cost of ownership, including maintenance and programming updates.

By addressing these issues early, SMEs can ensure their robotic machine investments remain cost effective and future-proof.

6. Custom End Effectors: Solving Complex Case Packing Challenges

Standard grippers cannot meet every SME requirement. Custom end of arm tooling delivers tailored solutions for specific tasks and improves performance in high mix environments.

Types of end effectors:

| End Effector Type | Best For | Limitations |

|---|---|---|

| Vacuum grippers | Lightweight, uniform packaging | Limited on porous or irregular surfaces |

| Mechanical grippers | Heavy items, rigid materials | Less effective on fragile products |

| Hybrid systems | Mixed SKUs and fragile goods | Higher initial investment |

Use cases include handling fragile goods, irregular shapes, and low volume production runs with frequent changeovers. For SMEs, custom robotic arms paired with intuitive programming deliver consistent quality while maintaining flexibility.

7. Flexible Packaging Automation: When and How to Upgrade

Over time, packaging lines become bottlenecks for SMEs. Signs it is time to upgrade include inability to meet demand spikes, difficulty handling diverse products, and ongoing recruitment challenges.

SMEs often begin with pilot projects when labour shortages or inefficiencies peak. As automation proves effective, robotic arms are scaled across production lines to increase production and meet market demands.

Features of flexible robotic packaging systems:

- Intuitive programming that enables fast redeployment.

- Compact footprint suitable for SMEs with limited shop floor space.

- Seamless integration with existing machines and processes.

- Increased productivity through consistent quality and reduced cycle time.

Investing in modular, scalable robotic systems positions SMEs for sustainable growth. Early adoption creates competitive advantage while reducing dependency on human operators for physically demanding tasks.

Final Thoughts

For small and medium sized enterprises, automation is no longer optional. Robotic machine tending, palletising robots, and packaging automation provide cost effective solutions that enhance productivity, address labour shortages, and improve workplace safety.

By starting with pilot projects and adopting collaborative robots with intuitive programming, SMEs can reduce reliance on human operators, perform tasks with consistent quality, and future-proof operations against changing market demands.

Have you considered how robotic machine tending could reshape your production lines? Share your thoughts in the comments below.

FAQs

What makes robotic machine tending for SMEs a cost effective solution?

Robotic machine tending reduces reliance on human workers for repetitive tasks and hazardous tasks. By starting with pilot projects, SMEs spread their initial investment and achieve ROI faster while enhancing productivity.

How do collaborative robots improve workplace safety in machine tending?

Collaborative robots equipped with force limiting technology minimise risks for human operators. They allow seamless integration into tight spaces without extensive safety caging, making them safer than traditional robots.

Can robotic arms handle high mix low volume production runs?

Yes, modern robotic systems with intuitive programming and custom end of arm tooling provide unparalleled flexibility. This enables SMEs to automate new tasks and manage high mix, low volume production without complex programming.

When should medium sized enterprises upgrade to flexible packaging automation?

Upgrading becomes essential when recruitment challenges persist and production lines cannot keep up with market demands. A modular robotic system with a compact footprint ensures consistent quality, increased productivity, and adaptability across various industries.