Cobots, through precision automation and AI-powered systems, help manufacturers reduce material waste, reduce energy consumption, and improve process efficiency.

The manufacturing sector is feeling the heat. Between soaring energy costs, stricter emission rules, and growing pressure to go green, businesses are being pushed to rethink how they work.

Enter collaborative robots or cobots. These clever machines are designed to work alongside humans, making manufacturing processes more efficient and sustainable.

They help cut energy consumption, reduce waste, and streamline operations - all without taking up too much space or power.

For manufacturers focused on sustainable practices, cobots are quickly becoming a smart investment.

What Are Collaborative Robots?

Cobots are compact, flexible robots made to work safely alongside people with minimal guarding. Thanks to advanced sensors and built-in safety features, they can detect human presence and adjust their movements to avoid accidents.

That makes them perfect for tasks like assembly, material handling, and quality checks. While cobots take care of repetitive or physically demanding jobs, human workers can shift to more strategic or creative roles.

It’s a win for safety, efficiency, and employee well-being.

Reducing Material Waste Through Precision

In traditional manufacturing, human error and inconsistent processes often lead to wasted materials. Cobots help fix that.

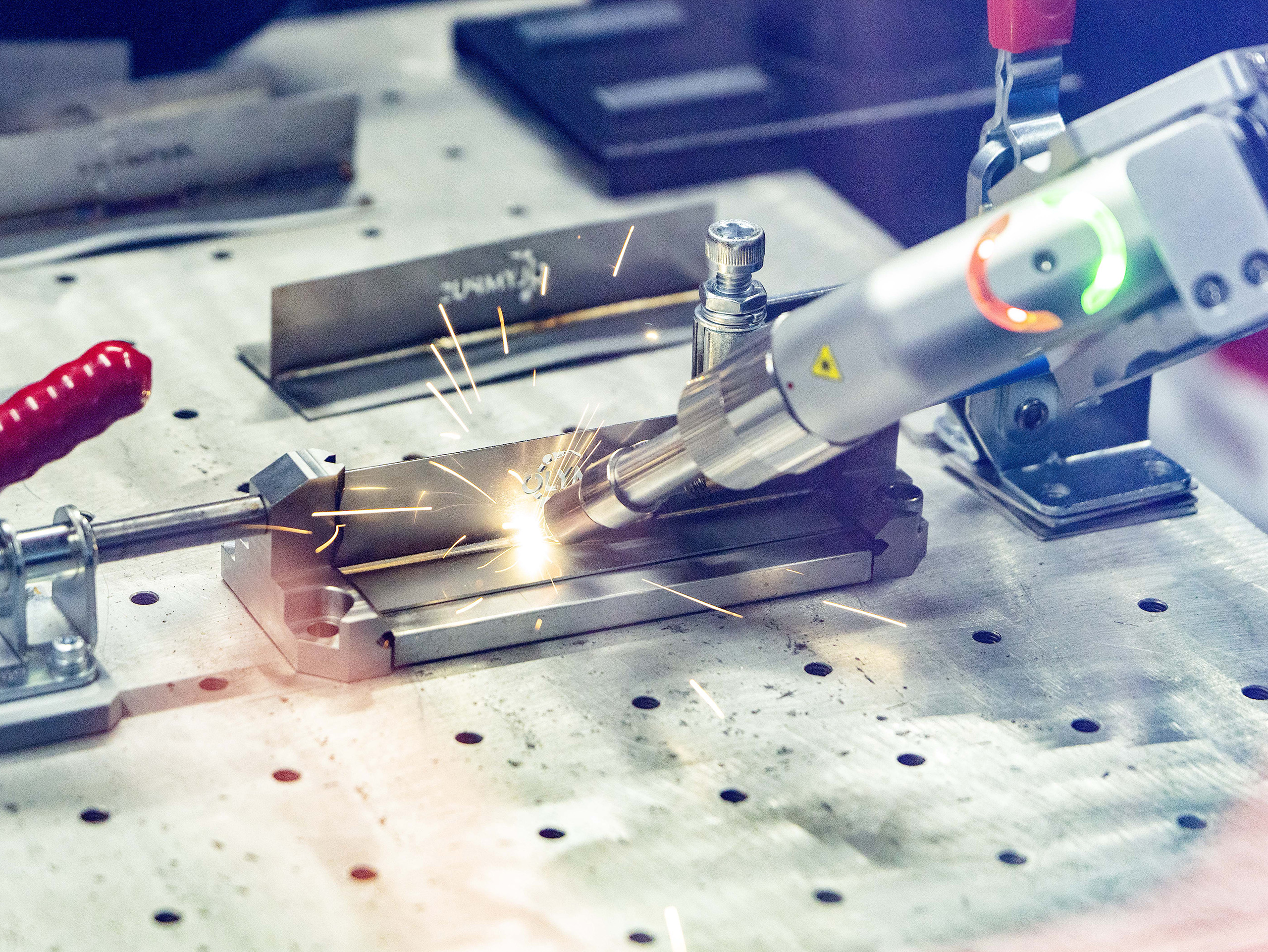

They perform tasks with high precision and repeatability. Whether it’s welding, palletising, or machine tending, cobots handle materials more accurately. This cuts down on material waste and helps improve overall product quality.

Key Waste-Reducing Benefits

- Fewer defects due to consistent quality

- Better use of raw materials

- Lower scrap rates - up to 30% reduction (McKinsey & Company)

Cobots also support zero-defect manufacturing goals. They stick to set standards and maintain consistent cycle times, helping manufacturers meet both quality and sustainability targets.

Cutting Energy Use with Smart Design

Cobots are built with energy efficiency in mind. They’re lighter and more compact than traditional robots, and they use energy-efficient motors that require far less power.

What’s more, they don’t waste energy on unnecessary movements. Control algorithms plan the shortest, most efficient paths, which helps keep consumption low during every shift.

Energy-Saving Features

- Low-power motors and compact actuators

- Optimised motion paths to reduce idle running

- Real-time monitoring via smart factory systems

According to the International Energy Agency (IEA), smart automation like this can cut industrial energy use by as much as 25%. For companies aiming to minimise energy consumption, cobots offer real results.

Smarter Cobots with AI and Machine Learning

Artificial intelligence adds another layer of efficiency. AI-powered cobots use real-time data to fine-tune their actions and improve performance.

They can predict production demands, adjust work cycles, and even spot potential breakdowns before they happen.

AI Capabilities That Boost Efficiency

- Predictive maintenance capabilities to reduce unplanned downtime

- Energy use adjusted to off-peak hours

- Dynamic scheduling for leaner operations

This leads to better uptime, less energy use, and more efficient manufacturing processes overall.

Supporting People, Not Replacing Them

Cobots aren’t here to take jobs - they’re here to make them better. By stepping in on physically demanding tasks, cobots reduce the risk of injury and repetitive strain.

That leaves human workers free to focus on higher-value jobs. It also opens doors for upskilling in robotics, programming, and system maintenance.

Human-Focused Benefits

- Fewer injuries from manual labour

- Higher employee satisfaction

- New career paths in advanced robotics

This human-robot collaboration is changing how manufacturers think about their workforce. It’s safer, smarter, and more sustainable.

Powering Sustainable Manufacturing Initiatives

Cobots aren’t just tools - they’re part of a bigger strategy for sustainable operations. They help companies hit energy and emission targets, reduce waste, and improve overall resource planning.

By connecting with smart factory systems, cobots can track everything from energy use to supply chain impact. This data-driven insight supports long-term sustainable manufacturing initiatives.

Cobot Contributions to Sustainability

- Meet carbon reduction and energy efficiency goals

- Support low-emission, eco-friendly processes

- Improve traceability and reduce waste across global supply chains

Cobots bring sustainable practices to life, not just within factories, but across entire manufacturing businesses.

Making the Switch: How to Get Started

Implementing cobots takes planning. Start by reviewing current manufacturing operations to find where cobots can make the biggest impact - usually in repetitive, labour-intensive, or energy-heavy tasks.

Think beyond the production line. Cobots can also be integrated with other robotic systems and industrial robots to build a connected, intelligent manufacturing setup.

Using remote monitoring tools can help teams track cobot performance in real time, so they’re always running at peak efficiency.

Cobot vs. Traditional Robots: A Quick Comparison

| Feature | Traditional Robots | Cobot-Integrated Systems |

|---|---|---|

| Energy Use | High | Low and optimised |

| Waste Control | Reactive | Precise and measurable |

| Human Involvement | Limited | Collaborative and safe |

| Maintenance | Reactive | Predictive and efficient |

| Accuracy | Variable | Consistent and repeatable |

This shift toward robotic automation not only saves time and resources, it helps companies take a big step toward a sustainable future.

Real-World Results

The automotive industry has been leading the way. Companies like BMW and Volkswagen use cobots for assembly tasks, inspection, and material handling. The result? Less waste, lower emissions, and more efficient production.

The same goes for sectors like electronics and pharmaceuticals. Cobots help maintain quality, cut waste, and support clean, lean processes - all crucial for meeting modern environmental concerns.

Manufacturers like Universal Robots and KUKA offer cobots that are easy to set up, safe to operate, and ideal for different industries. And as demand grows, they’re also helping create new jobs in tech and robotics.

Conclusion: A Smart Move for Sustainability

If your goal is to reduce costs, save energy, and make your business greener, cobots are a clear solution.

They support sustainable manufacturing practices by cutting waste, lowering energy use, and improving overall efficiency. They also protect workers and create new opportunities in an evolving manufacturing landscape.

Cobots aren’t just about meeting today’s goals. They’re about future-proofing your business for what’s next.

At Olympus Technologies, we specialise in plug-and-play cobot solutions that support your journey to sustainable success. Whether you’re in automotive, electronics, or beyond, we’ll help you get the most out of your cobot investment - without running them at full speed all the time, because that saves energy too.

Ready to take the next step? Talk to us today about how cobots can help transform your manufacturing processes for the better.