Welcome to the future of manufacturing - where collaborative robots (aka cobots) and CNC machines team up to get the job done faster, safer, and more precisely.

Whether you're running small batches, dealing with labour shortages, or just want to make better use of your team’s time, integrating cobots into your machine tending workflow could be a game changer.

Let’s break down how it all works (without the jargon overload), what tech makes it possible, and why businesses like TROX UK are already seeing the benefits.

What’s the Deal with Cobots and CNC Machines?

Cobots are designed to work right alongside human operators – no cages, no drama.

Thanks to smart sensors, force-limited joints, and built-in safety standards (ISO 10218 & ISO/TS 15066), they’re safe to use even in tight spaces. CNC machines, on the other hand, are your go-to tools for shaping parts – think mills, lathes, and press brakes.

When you combine the two, you get a collaborative automation system that’s efficient, flexible, and well-suited to the kind of high-mix, low-volume work that’s tricky to automate with traditional methods (Bystronic, 2023).

Why It Works: Key Benefits

1. More Operational Time

Cobots can run 24/7. One manufacturer added 1,200+ hours of annual machining time just by integrating a robot - and hit 95% utilisation (Universal Robots).

2. Consistent Precision

No more fatigue-induced errors. Cobots position each part exactly the same, every time. That means fewer scrapped components and tighter quality control.

3. Flexibility for Any Job

Cobots are easy to reprogram and redeploy. You can move them between machines, change setups for different batch sizes, or let a person take over for manual operation when needed.

4. Improved Safety & Ergonomics

They handle the heavy lifting and repetitive work - especially around sharp tools or hot parts – so your team can focus on supervision, custom programming, and inspections.

CNC Machine Tending: Where Cobots Shine

Tending a CNC machine involves loading raw materials and unloading finished parts. Cobots do this tirelessly and with precision. They can also:

- Sort and inspect parts using vision systems

- Handle deburring, washing, or measuring components

- Adapt to larger or smaller parts using reconfigurable gripping tools

This kind of automated process keeps machines running continuously with minimal downtime between cycles.

The Tech That Makes It Happen

Here’s what makes modern cobot-powered systems so capable:

1. Multi-Circuit Pneumatic Gripper

Devices like the Scorpion gripper feature extendable pinch gripping to handle different part sizes securely.

2. Integrated Rotational Cylinder

This lets the robot mounted gripper rotate parts mid-process – essential for accurate placement during press brake or bending automation.

3. High-Resolution Distance Sensor

Used for detecting infeed part stacks, stack height, and tiny part variations (even thin sheet metal around 0.5mm thick).

4. Custom Programming Templates

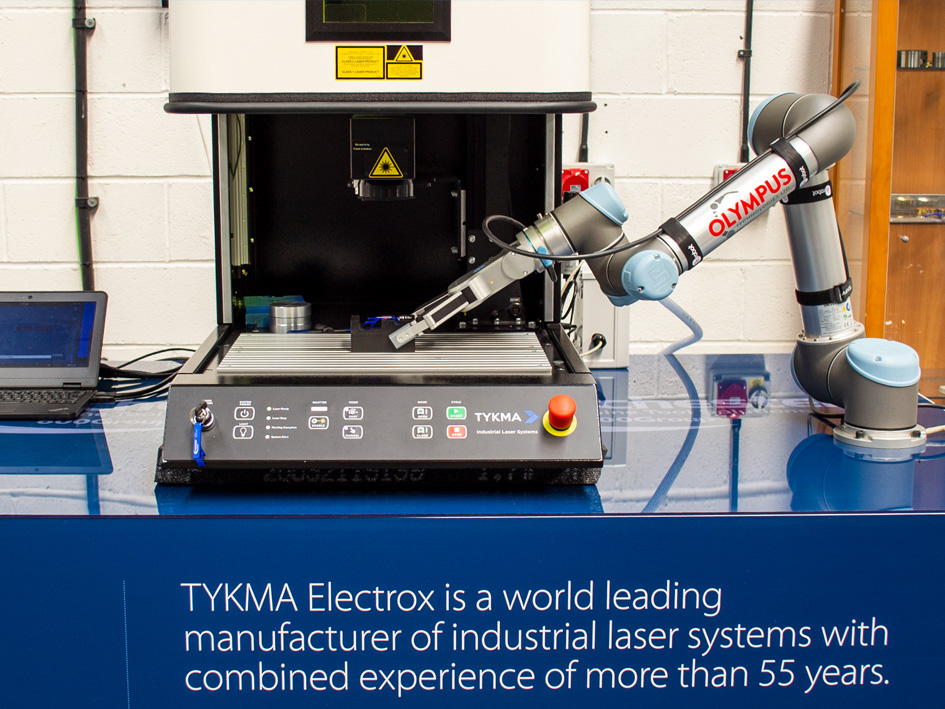

Companies like Olympus Technologies offer bespoke software and templates for fast setup – ideal for robotic press brake tending.

5. Mobile Trolley with Single Cable Hookup

Easily move your cobot mounted system between machines, or roll it away for odd occasions that need manual operation.

Press Brake Automation in Action

Automating the press brake process solves several challenges:

- Accuracy: Cobots ensure repeatable, clean bends every time.

- Productivity: Run overnight jobs and walk in to a stack of finished parts the next morning.

- Staffing: Filling the gap left by experienced press brake operators is tough – cobots help bridge it.

- Flexibility: Easily switch between robotic press brake operation and manual work as needed.

One standout example is TROX UK, who turned to Olympus Technologies for a press brake tending cobot solution. Read about the impressive benefits in the Trox UK Ltd Case Study.

What to Know Before You Get Started

Safety Comes First

Follow proper safety standards and conduct a full risk assessment. Cobots have built-in limitations, but extra sensors, guarding or scanners may be needed depending on your layout.

Integration Is Key

Make sure your cobot communicates with your CNC machine via digital I/O or software triggers. Want next-level control? Connect it to your ERP or MES for real-time updates and job scheduling.

Train Your Team

Modern teach pendants are intuitive, but some training is still needed. The goal? Let your staff members focus on effortless control and higher-value work, while the cobot handles the grind.

Advanced Applications

Cobots aren’t just for material handling. They’re also being used for:

- Welding

- Palletising

- Laser Welding

- Case Packing

- Palletising

- Laser Marking

- Dispensing

- Quality Inspection

- In-process inspection using vision systems

In some setups, two cobots handle different steps in a process – loading, welding, inspecting – with both programming done in the same interface.

Final Thoughts: Cobots Are the Future

Combining cobots with CNC machines is no longer experimental - it’s the new normal. With new technologies, flexible setups, and software designed to simplify programming time, cobots are helping manufacturers:

- Tackle labour shortages

- Improve part quality

- Increase production without increasing headcount

- Stay competitive in a high-mix world

Whether you’re looking to automate your press brake machine, reduce downtime, or get more from each shift, a collaborative robot might just be the best investment you’ll make.

And if you need a hand? Companies like Olympus Technologies are integrator-capable and backed by service experts who can guide you through setup, training, and ongoing support.